Understanding the Single-Screw Extrusion Spinneret

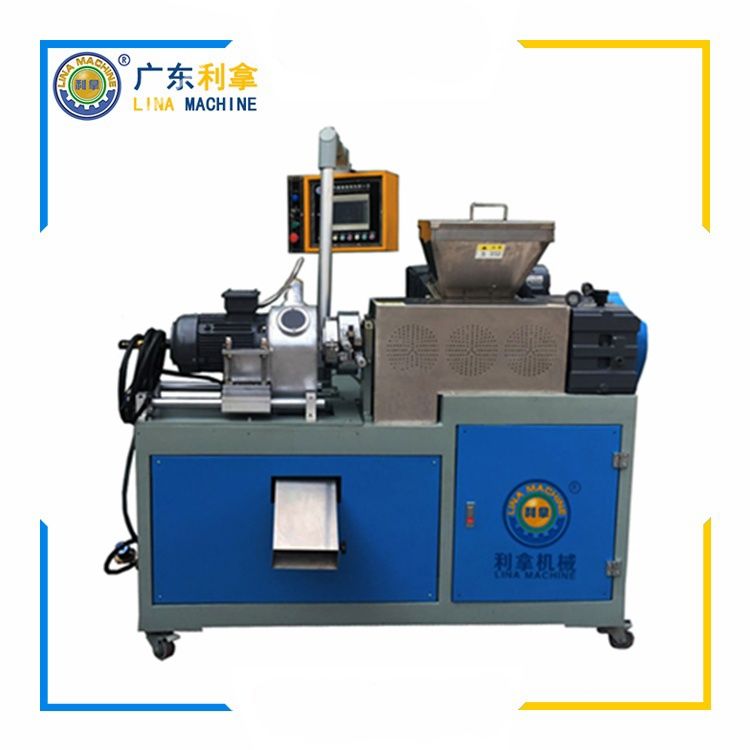

The single-screw extruder is a versatile and efficient tool in the polymer processing industry. It is widely used for producing various types of plastic products, such as pellets, films, and sheets. In this article, we will explore the basic principles of operation, key features, and applications of this machine.

At its core, the single-screw extruder consists of a rotating screw that pushes molten polymer through a die into a solidified form. The screw has several important functions: it mixes the raw materials, heats them to the desired temperature, and forces them through the die to create the final product.

One of the most significant advantages of the single-screw extruder is its ability to produce high-quality pellets. This is achieved by controlling the screw speed, temperature, and pressure during the extrusion process. By adjusting these parameters, manufacturers can achieve the desired physical properties, such as strength, flexibility, and impact resistance, of their products.

Another critical feature of the single-screw extruder is its ability to handle a wide range of polymers. This is due to the fact that the screw design allows for easy mixing and melting of different types of polymers. Additionally, the extruder's internal components are made from materials that are resistant to chemical degradation, ensuring long-term reliability and stability in production processes.

In conclusion, the single-screw extruder is an essential piece of equipment in the polymer processing industry. Its ability to produce high-quality pellets and its versatility make it a valuable tool for manufacturers looking to optimize their production processes. As technology continues to advance, we can expect to see even more innovative designs and improvements in this field.