The Development and Application of Foamed Silica Gel Pressing Production Line

The foamed silica gel pressing production line is a crucial equipment in the field of silicone products manufacturing. It plays a significant role in enhancing the quality and efficiency of silicone products, such as silicone elastomers, silicone sealants, and silicone adhesives. In this article, we will introduce the development process of the foamed silica gel pressing production line, its application in various fields, and its future development prospects.

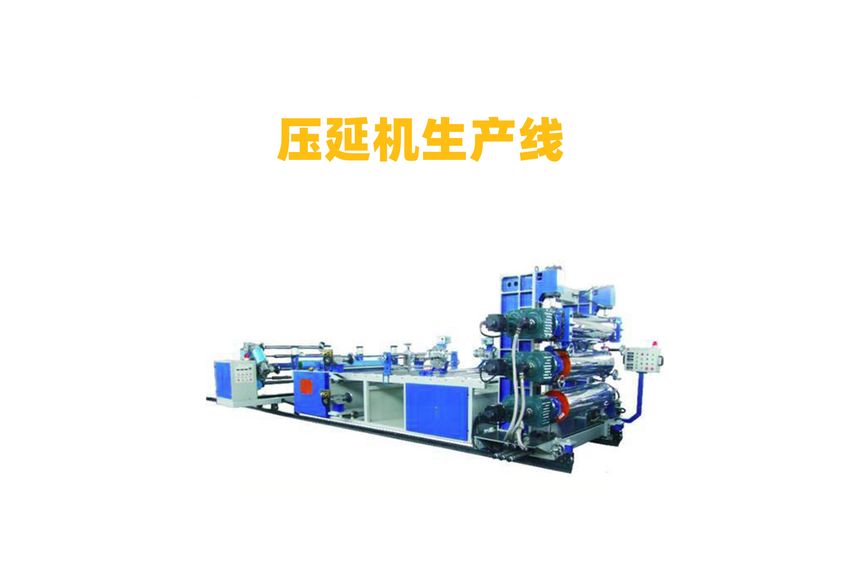

The foamed silica gel pressing production line is a complex system that includes several key components, such as the molding machine, pressure plate, heating system, cooling system, and packaging device. The molding machine is responsible for shaping the raw materials into desired shapes, while the pressure plate ensures uniform pressure during the molding process. The heating system provides heat to melt the raw materials, while the cooling system cools down the molded product to prevent cracking. Finally, the packaging device packages the finished product for further processing or sale.

The foamed silica gel pressing production line has been widely used in the manufacturing of silicone products due to its high precision, fast speed, and good repeatability. It can produce silicone elastomers with excellent mechanical properties, such as high elasticity, low compression set, and good fatigue resistance. Additionally, it can also produce silicone sealants and adhesives with good adhesion strength and chemical stability.

In recent years, the foamed silica gel pressing production line has also been applied in other fields, such as electronics, automotive, and aerospace. For example, in the electronics industry, it can be used to produce flexible printed circuit boards with high density and low weight. In the automotive industry, it can be used to produce engine mounts and fuel tanks with high strength and toughness. In the aerospace industry, it can be used to produce spacecraft parts with high precision and reliability.

Looking ahead, the foamed silica gel pressing production line will continue to develop and improve in terms of technology, automation, and intelligence. With the help of advanced sensors and control systems, the production line will become more intelligent and efficient. Additionally, new materials and technologies will be introduced to enhance the performance of the production line and meet the needs of different industries.

1. Foamed silica gel pressing production line

2. Silicon elastomers

3. Silicone sealants

4. Silicone adhesives

5. Manufacturing technology

6. Automotive industry

7. Aerospace industry

8. Intelligent automation

9. New materials and technologies

10. Performance improvement

This article provides an in-depth analysis of the foamed silica gel pressing production line, highlighting its importance in the field of silicone products manufacturing. We discuss its development process, application in various industries, and future development prospects. By analyzing the key components and functions of the production line, we aim to help readers better understand its advantages and potential applications. Additionally, we also explore the latest technological advancements and innovations in the field of silicone products manufacturing, providing valuable insights for professionals and enthusiasts in this field.