Understanding the Forced Feed Extruder

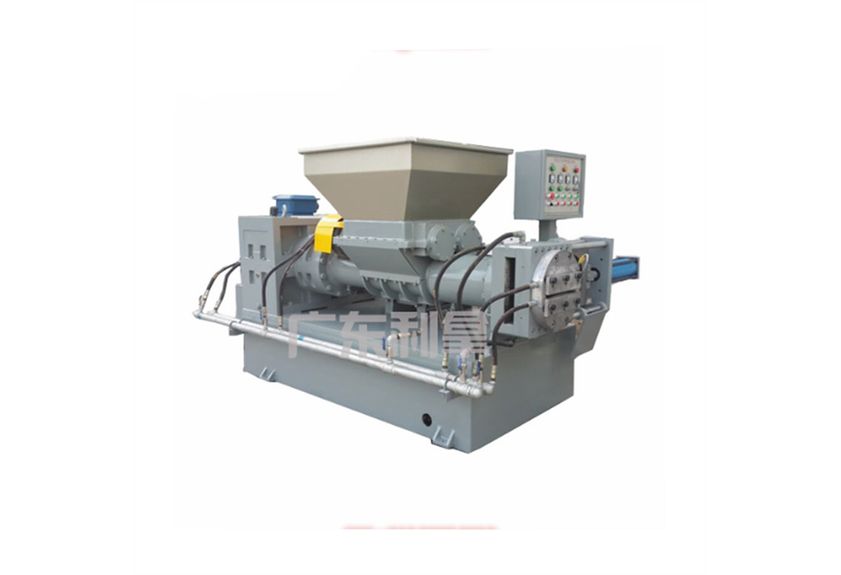

The forced feed extruder is a versatile and efficient tool in the manufacturing industry. It is designed to process materials such as plastics, rubber, and even metals, using a continuous feeding system that ensures uniform distribution of the material throughout the extrusion process. This machine is essential for industries that require high-quality products with consistent properties, such as automotive, electronics, and construction.

One of the key features of the forced feed extruder is its ability to handle a wide range of materials with different melting points and flow characteristics. The machine's advanced control system allows for precise temperature regulation and speed adjustment, ensuring that the material is processed at the optimal conditions for its particular application. Additionally, the extruder's design incorporates features such as adjustable dies and screw profiles to accommodate a variety of product shapes and sizes.

In operation, the forced feed extruder begins by feeding the raw material into the hopper. This material is then transported through a series of heating elements that gradually increase its temperature until it reaches the desired processing temperature. Once the material has reached the correct temperature, it is pushed through the die, which defines the final shape of the product. The extruded material then exits the die and enters the cooling section, where it is cooled down to prevent crystallization and maintain its consistency.

The force applied during the extrusion process is crucial for achieving the desired product quality. The extruder uses a combination of mechanical and electrical forces to push the material through the die and onto the冷却部分。This combination of forces ensures that the material is processed evenly and consistently, resulting in a product with consistent properties and no defects.

In conclusion, the forced feed extruder is an essential tool in the manufacturing industry for producing high-quality products with consistent properties. Its ability to handle a wide range of materials and its advanced control system make it a valuable asset for any industry seeking to produce reliable and durable products. By understanding the principles behind this machine and how it works, manufacturers can optimize their production processes and achieve greater efficiency and productivity.