Understanding the PE Trolley Machine: A Comprehensive Guide to its Function and Applications

The PE Trolley Machine, also known as the Plastic Extrusion Machine, is a crucial tool in the plastic industry. It is used to extrude thermoplastic sheets into long, thin strips that can be molded or cut into various shapes. This machine plays a significant role in the production of various products such as toys, packaging materials, automotive parts, and more. In this article, we will explore the functions of the PE Trolley Machine, its components, and how it works.

Functions of the PE Trolley Machine:

1. Extrusion: The PE Trolley Machine's primary function is to extrude thermoplastic sheets into long, thin strips. The process involves heating the sheet material to a high temperature, which causes it to flow and become malleable. Then, the material is forced through a die, which defines the final shape of the strip.

2. Mold Making: The PE Trolley Machine can also be used to make molds for different products. By using specialized tools, the machine can create precise shapes for molds made of thermoplastic sheets.

3. Cutting: Once the strip has been formed into the desired shape, it can be cut into smaller pieces using a cutting blade. This allows for easy transportation and assembly of the product.

4. Quality Control: The PE Trolley Machine is equipped with sensors and control systems that ensure consistent quality throughout the production process. These systems monitor the temperature, pressure, and speed of the machine to maintain optimal conditions for producing high-quality products.

Components of the PE Trolley Machine:

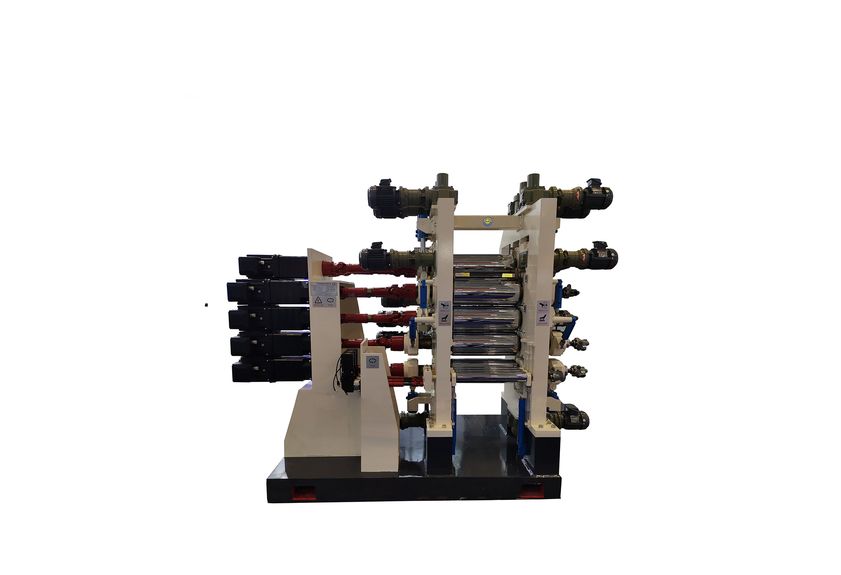

The PE Trolley Machine consists of several key components that work together to produce the desired product. Here are some of the most important components:

1. Die: The die is the essential component of the PE Trolley Machine. It defines the shape of the extruded strip and determines the thickness and width of the material. There are various types of dies available, including round, square, and custom shapes, depending on the specific needs of the manufacturer.

2. Die Holder: The die holder holds the die in place during the extrusion process. It ensures that the die remains stable and does not move during the manufacturing process.

3. Extruder Head: The extruder head is responsible for feeding the thermoplastic sheet into the machine. It consists of a hopper, screw, and barrel assembly that mixes and heats the material before it enters the die.

4. Cooling System: The cooling system helps to cool down the material after it has been extruded. This prevents the material from overheating and reduces the risk of defects such as warping or cracking.

5. Transportation System: The transportation system is responsible for moving the finished product from the machine to the packaging or shipping area. It includes conveyor belts, stackers, and other equipment designed to handle large quantities of material efficiently.

How Does the PE Trolley Machine Work?

The PE Trolley Machine operates by first heating the thermoplastic sheet to a high temperature. This process is typically done using an electric resistance heater or a gas burner. Once the material has reached the desired temperature, it is forced through a die by a motorized screw. The screw rotates at a high speed, causing the material to flow and become malleable. As the material exits the die, it is guided onto a cooling system where it is cooled down quickly. This process repeats until the entire sheet has been extruded and formed into a long, thin strip. Finally, the strip is cut into smaller pieces using a cutting blade and ready for further processing or packaging.

1. PE Trolley Machine

2. Extrusion Process

3. Molding

4. Cutting

5. Quality Control

6. Die Holder

7. Extruder Head

8. Cooling System

9. Transportation System

10. Production Process

The PE Trolley Machine is a critical tool in the plastic industry that plays a vital role in the production of various products such as toys, packaging materials, automotive parts, and more. Its main function is to extrude thermoplastic sheets into long, thin strips that can be molded or cut into various shapes. The PE Trolley Machine's components include a die, die holder, extruder head, cooling system, transportation system, and more. The machine operates by heating the material to a