The Art of Silicone Rolling Machines

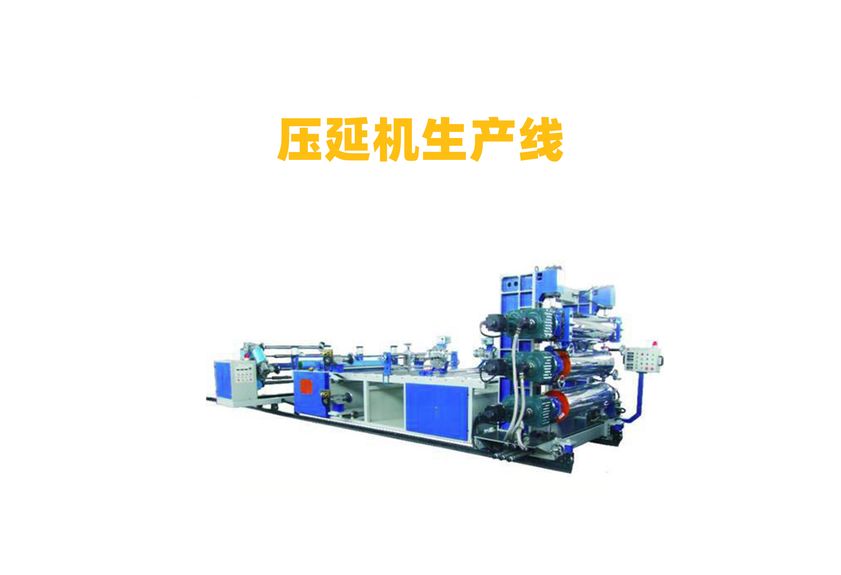

Silicone rolling machines are an essential tool in the manufacturing industry, particularly in the production of silicone products. These machines are designed to roll silicone sheets or films into a uniform thickness and width, which is crucial for their subsequent use in various applications such as electronics, automotive, and aerospace industries.

One of the key features of a silicone rolling machine is its ability to handle different types of silicone materials with ease. This is achieved through the use of specialized rollers that can adapt to the specific properties of the silicone being processed. For example, some machines may have rollers made from high-temperature resistant materials, while others may have rollers that are specifically designed to handle low-temperature silicone.

Another important aspect of silicone rolling machines is their precision control system. This system allows for precise adjustments in the thickness and width of the rolled silicone, ensuring consistency in the final product. This is particularly useful when producing custom-sized silicone parts or when working with complex designs that require precise dimensional control.

In addition to these technical features, silicone rolling machines also come with several safety features. These include automatic停止 mechanisms that prevent overheating and excessive pressure on the silicone material, as well as emergency shutdown buttons that allow operators to quickly stop the machine if necessary.

Overall, silicone rolling machines play a vital role in the modern manufacturing process, allowing for the efficient and accurate production of silicone products. By leveraging their advanced features and safety measures, manufacturers can ensure that their products meet the highest standards of quality and reliability.