The Role of the Grinding Film Rolling Press in Manufacturing

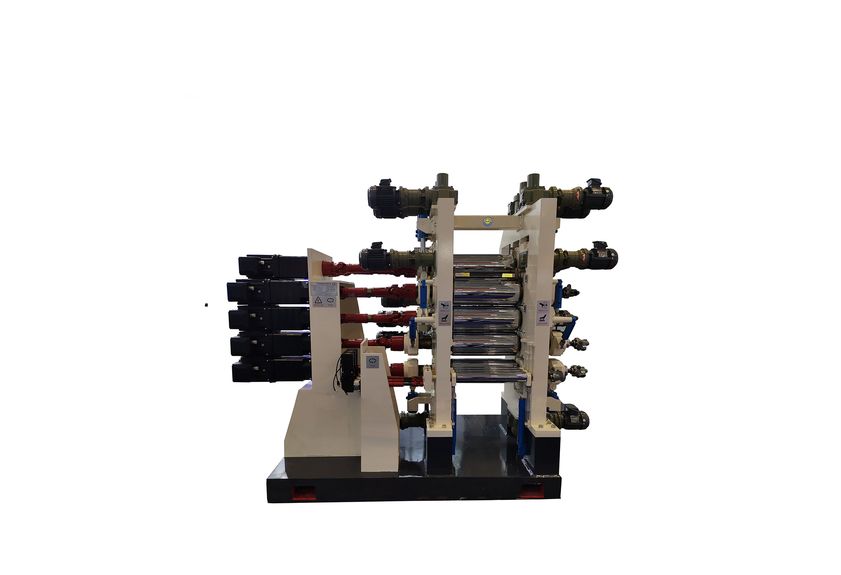

The grinding film rolling press is a crucial tool in the manufacturing industry, particularly in the production of electronic components and semiconductors. This machine uses a thin layer of graphite as its base material to create a smooth surface for subsequent processing steps. The graphite film is applied to the surface of a metal sheet or plate, which is then pressed together using a pair of rollers. The resulting pressure and temperature cause the graphite to melt and flow, creating a uniform layer on the metal surface. This process not only improves the quality of the final product but also reduces waste and saves time. In addition, the grinding film rolling press can be used to produce various shapes and sizes of metal sheets, making it an essential piece of equipment in many industrial settings.

1. Grinding Film Rolling Press

2. Electronic Components

3. Semiconductors

4. Metal Sheet

5. Processing Steps

The grinding film rolling press plays a vital role in the manufacturing industry by providing a smooth surface for subsequent processing steps. This innovative machine uses a thin layer of graphite as its base material, which is melted and flowed under high pressure and temperature to create a uniform layer on the metal surface. The resulting product is not only of high quality but also reduces waste and saves time. Furthermore, this machine can produce various shapes and sizes of metal sheets, making it an essential piece of equipment in many industrial settings.