The Role of Rubber Extrusion Machinery in the Manufacturing Industry

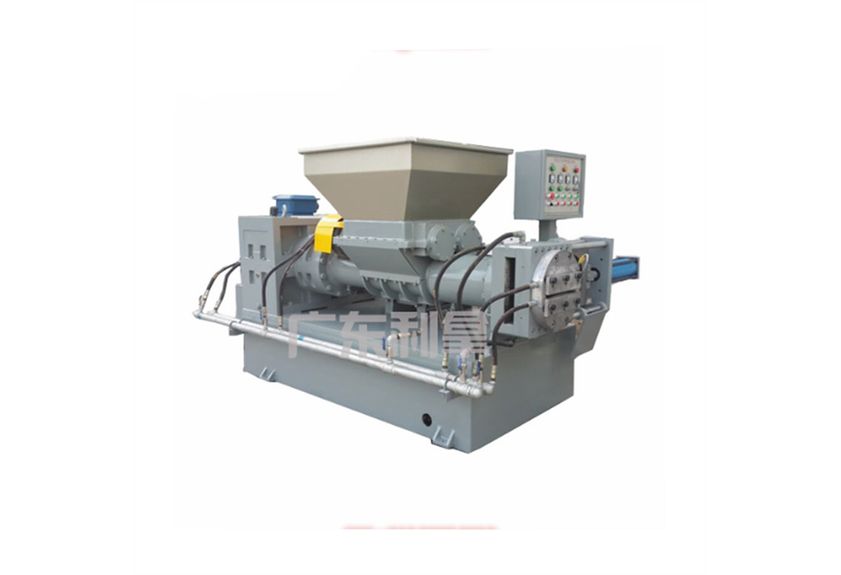

The rubber extrusion machinery is an essential tool in the manufacturing industry, particularly in the production of various types of rubber products. It is a complex system that involves several components such as the screw, barrel, and die. The process of rubber extrusion involves mixing the raw materials, which are typically natural or synthetic rubber compounds, with additives such as carbon black, fillers, and plasticizers. These mixtures are then forced through a die, which defines the final shape and size of the product. The extruded material is then cooled and solidified to form the final product.

The rubber extrusion machine plays a crucial role in the manufacturing process by providing a consistent and reliable output. It ensures that the raw materials are evenly mixed and that the die is properly aligned to produce the desired product. The machine also helps to control the temperature and pressure during the extrusion process, which can affect the quality and properties of the final product.

In addition to its technical functions, the rubber extrusion machine is also an important part of the manufacturing process. It allows for the efficient production of large volumes of rubber products, which would be difficult or impossible to produce manually. This makes it an essential tool for businesses that rely on mass production of rubber products.

Overall, the rubber extrusion machine is a critical component of the manufacturing industry, providing a reliable and efficient way to produce a wide range of rubber products. Its ability to handle large volumes of material and its ability to control the process parameters make it an indispensable tool for any manufacturing operation.