Article Title: The Automated E...

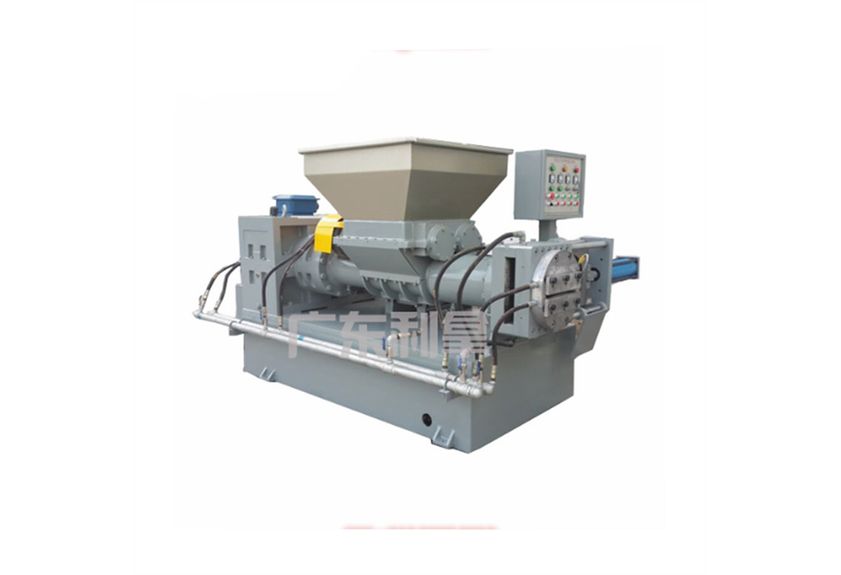

Article Title: The Automated Extrusion and Filtration Machine - A Revolution in Processing Technology

Introduction

In the realm of industrial processing, the ability to efficiently handle materials and produce consistent outputs is paramount. This is where the automated extrusion and filtration machine comes into play, offering a solution that has transformed the way we approach manufacturing processes.

Key Features of the Automated Extrusion and Filtration Machine

#1. Robust Design

The machine boasts a robust design that can withstand the rigors of heavy-duty operations. Its sturdy construction ensures longevity and minimizes downtime, making it an ideal choice for industrial settings.

#2. Advanced Technology

The automation of the process is achieved through cutting-edge technology, ensuring precision and efficiency. The machine's advanced control system allows for precise temperature regulation, speed adjustments, and other critical parameters, resulting in consistent product quality.

#3. Seamless Integration

The machine's integration capabilities are unparalleled, allowing for seamless integration with existing production lines. This not only enhances productivity but also streamlines the overall process, reducing waste and maximizing efficiency.

#4. Environmentally Friendly

The machine's design incorporates environmentally friendly features, such as energy-efficient motors and eco-friendly materials. This not only reduces operating costs but also aligns with modern sustainability trends.

Benefits of the Automated Extrusion and Filtration Machine

#1. Cost Efficiency

One of the most significant benefits of the automated extrusion and filtration machine is its cost-effectiveness. By eliminating manual labor and reducing the need for frequent maintenance, businesses can save significant amounts of money on operational expenses.

#2. Product Quality

The machine's advanced technology ensures consistent product quality, minimizing defects and improving product consistency. This not only enhances customer satisfaction but also increases market competitiveness.

#3. Continuous Production

With its seamless integration capabilities, the automated extrusion and filtration machine enables continuous production, meeting the demands of fast-paced markets. This not only boosts productivity but also ensures timely delivery of products to customers.

#4. Environmental Sustainability

The machine's use of eco-friendly materials and energy-efficient technologies promotes sustainable practices. By adopting this approach, businesses can demonstrate their commitment to environmental responsibility and attract customers who value sustainability.

Conclusion

The automated extrusion and filtration machine represents a significant advancement in industrial processing technology. Its robust design, advanced technology, seamless integration capabilities, and environmentally friendly features make it an essential tool for any modern-day manufacturing operation. As the demand for efficient and high-quality products continues to grow, the automated extrusion and filtration machine will undoubtedly become an indispensable asset for businesses looking to stay ahead of the competition.