The Art of Silicone Roll Compaction Machines: A Detailed Look at the Five-Roller Type

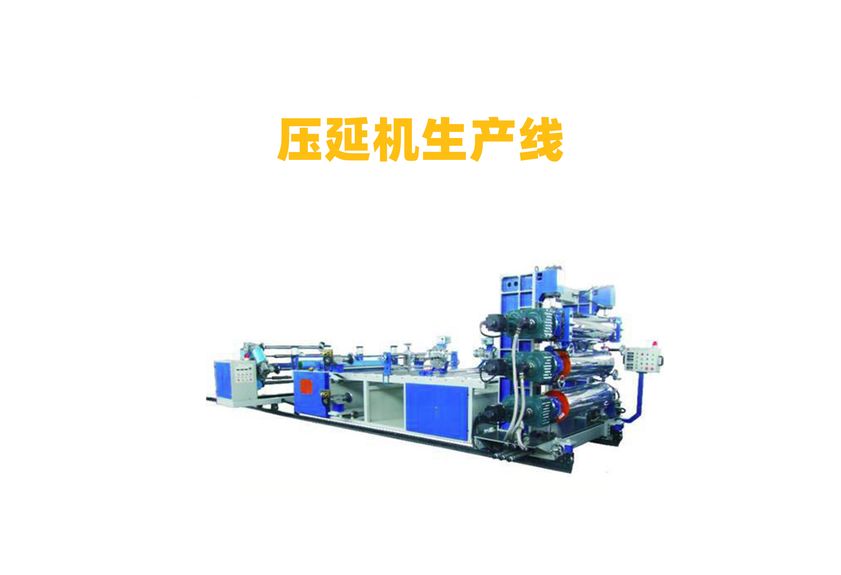

The art of silicone roll compaction machines is a fascinating field that has been refined over time. These machines are crucial in the production process of various silicone products, from flexible hoses to seals and gaskets. The five-roller type is one of the most popular models due to its efficiency and reliability. In this article, we will delve into the details of this innovative machine and its unique features.

Firstly, let's understand what a five-roller silicone roll compaction machine is. It is a versatile tool that uses five rollers to compress and shape silicone sheets or sheets of material. This process helps in achieving a uniform thickness and density throughout the product, which is essential for its performance and durability.

The first roller is responsible for shaping the silicone sheet and ensuring it is evenly distributed across the entire width. The second roller then follows, adding more pressure to the sheet, while the third roller takes over by further consolidating the material. The fourth and fifth rollers work together to smooth out any rough edges or uneven surfaces, resulting in a finished product with a consistent appearance.

One of the key advantages of using a five-roller silicone roll compaction machine is its ability to handle a wide range of materials. Whether you are working with silicone rubber sheets, foam sheets, or other types of flexible materials, this machine can adapt to your specific needs. Additionally, its precision control system ensures that each layer of the product is precisely applied, resulting in a high-quality end product.

Another significant advantage of this machine is its efficiency. Compared to manual methods, using a five-roller silicone roll compaction machine saves time and resources. The machine's automated functions make it possible to produce large batches of silicone products quickly and efficiently. This not only reduces labor costs but also improves overall productivity.

In conclusion, the five-roller silicone roll compaction machine is an essential tool for anyone involved in the production of silicone products. Its ability to handle a wide range of materials and its precision control system make it a reliable choice for businesses looking to produce high-quality silicone products. As technology continues to advance, we can expect to see even more innovative models emerge, further enhancing the capabilities of these machines.