The Role of Polymer Granulation Machines in the Manufacturing Industry

The manufacturing industry has seen a significant increase in demand for high-quality polymer materials, which require precise control over their properties. One of the critical steps in the production process is the granulation of polymers, where they are transformed into small, uniform particles that can be easily handled and processed further. This process is crucial for various applications such as plastics, rubber, and composite materials.

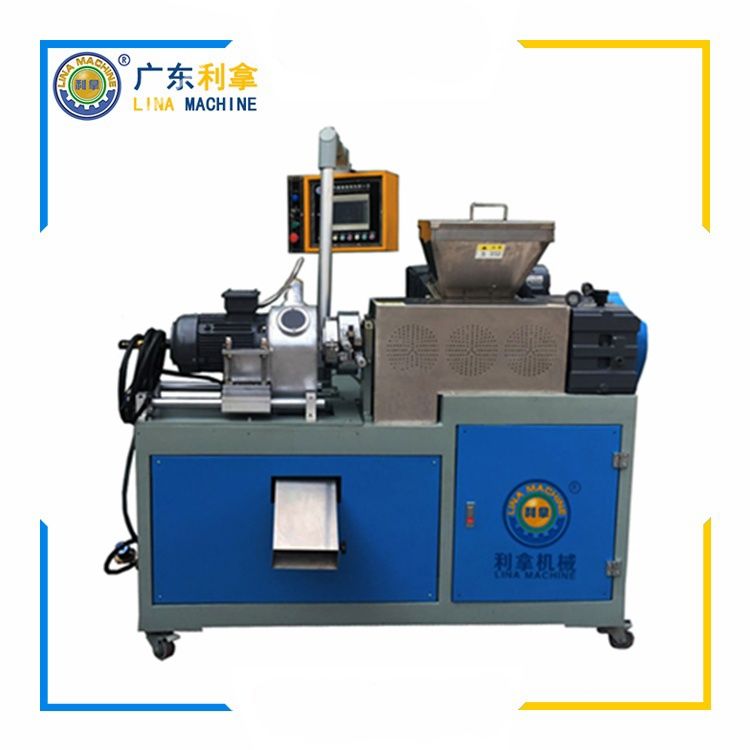

Polymer granulation machines play a vital role in this process by providing efficient and accurate granulation of polymers. These machines use different techniques to achieve the desired particle size, shape, and distribution. Some of the common methods used in granulation machines include melt extrusion, dry granulation, and wet granulation.

Melt extrusion is a popular technique used in granulation machines, where polymers are melted and forced through a die to form small beads or pellets. This method is widely used in the production of thermoplastics and elastomers. Dry granulation involves the use of a granulating agent, such as calcium carbonate, to coat the polymer particles before they are dried. This method is commonly used in the production of thermosets and thermoplastics. Wet granulation involves the use of a solvent to dissolve the polymer and then remove the solvent, leaving behind the granulated material. This method is commonly used in the production of thermosets and elastomers.

The choice of granulation machine depends on the type of polymer and the desired particle size and shape. For example, melt extrusion is commonly used for thermoplastics, while dry granulation is preferred for thermosets and thermoplastics. Wet granulation is suitable for thermosets and elastomers.

In conclusion, polymer granulation machines play a crucial role in the manufacturing industry by providing efficient and accurate granulation of polymers. Different techniques are used to achieve the desired particle size, shape, and distribution, depending on the type of polymer and the desired application.