The Role of the Film Extrusion Machine in Film Production

The film extrusion machine is an essential tool in the production process of films. It is a machine that uses heat and pressure to melt and shape plastic materials into a continuous filament. This filament is then used to create films, which are used in various applications such as packaging, advertising, and entertainment.

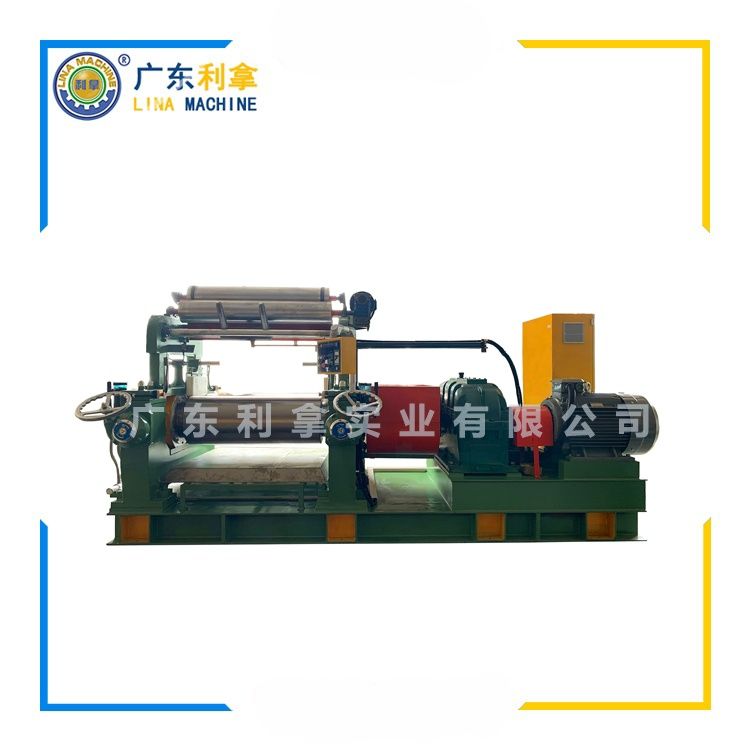

The film extruder consists of several parts, including the hopper, screw, die, and take-up reel. The hopper is where the plastic material is fed into the machine. The screw is responsible for mixing and distributing the material evenly through the machine. The die is the part that shapes the material into the desired film thickness. The take-up reel is used to wind up the film after it has been formed.

The film extrusion machine operates by heating the plastic material to a high temperature, causing it to flow and become molten. This molten material is then forced through the die by the screw, which creates a continuous filament. The filament is then wound onto the take-up reel, creating a continuous supply of film.

One of the key advantages of using a film extruder is its ability to produce films with consistent quality and thickness. This allows for precise control over the final product, which is important for many applications. Additionally, the use of this machine can save time and labor costs compared to other methods of film production.

In conclusion, the film extrusion machine plays a crucial role in the production of films. Its ability to produce films with consistent quality and thickness makes it an essential tool in the film industry. By utilizing this machine, filmmakers can achieve higher quality products while saving time and money.