Cold-Feed Rubber Extruder | Pin-Barrel & Vent-Type LN-E Series for Tire, Hose & Profile Production

Cold-Feed Rubber Extruder – Brief IntroductionA cold-feed rubber extruder (also called rubber cold-feed extruding machine, pin-barrel cold-feed extruder, vent-type cold-feed extruder, or cold-feed rub

TAG: cold-feed rubber extruder,pin-barrel cold-feed extruder,vent-type cold-feed extruder

Cold-Feed Rubber Extruder – Brief Introduction

A cold-feed rubber extruder (also called rubber cold-feed extruding machine, pin-barrel cold-feed extruder, vent-type cold-feed extruder, or cold-feed rubber block extruder) accepts rubber compound at ambient temperature. Through screw shearing, compression and precise temperature control, it realizes low-temperature plasticizing, degassing and continuous extrusion without pre-heating. Compared with traditional hot-feed systems, it eliminates warm-up mills, cuts energy consumption by 20–35 %, keeps stock temperature low and minimizes scorch risk, making it the core equipment for efficient production of tires, hoses, sealing strips, cables and other rubber products.

Guangdong LiNa LN-E Series Cold-Feed Rubber Extruder

—— 45 mm – 200 mm Full-Spec High-Plasticizing Solution

1. Key Features

1. High-compression-ratio screw

Patented wave-type + BM barrier design, compression ratio 2.4–2.8, full plasticizing at low temperature, reduced scorch.

2. Pin-type shearing zone (optional)

8–12 rows of radial pins, dispersion improved by 15–25 %, ideal for high carbon-black loading.

3. Smart temperature control

4–6 zones PID ceramic heaters + closed-loop water cooling, ±2 °C accuracy, 15 min heat-up.

4. Inverter + hardened-gear reducer

ABB/Siemens inverter, transmission efficiency ≥ 96 %, noise ≤ 78 dB(A).

5. Quick screen changer & self-cleaning

Hydraulic slide screen change ≤ 3 min; bidirectional mixing head prevents compound build-up.

6. Modular die head

Fast switch between sheet, tube or profile dies, supports flexible multi-product manufacturing.

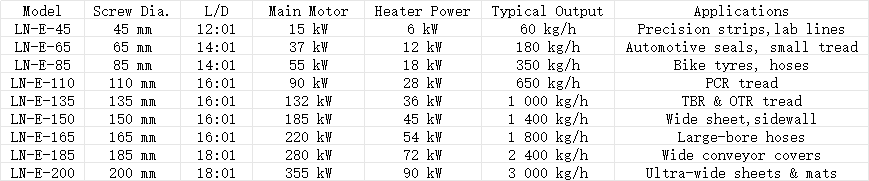

2. Models & Output

Actual output depends on compound hardness and formulation.

3. Applicable Materials & Products

Materials: NR, SBR, BR, NBR, EPDM, CR, IIR, CSM, ECO, silicone rubber, etc.

Products: tyre tread/sidewall, automotive sealing strips, hoses, cable sheaths, conveyor belts, anti-vibration pads, waterstop, sponge profiles, rubber sheets.

4. Standard Configuration

1) Main extruder (inverter, TCU, reducer)

2) Vertical forced-feed roll device

3) Hydraulic screen changer + gear pump (optional)

4) Die head (customized)

5) Control cabinet (Siemens PLC + 10" HMI)

6) Water/air-cooled haul-off, cutting & wind-up line (optional)

5. Warranty & Delivery

• Warranty: 12 months on complete machine, 24 months on screw & barrel

• Commissioning: free 3-day on-site training, lifetime technical support

• Lead time: 30 working days for standard models, 45–60 days for customized units

6. About Guangdong LiNa Industrial Co., Ltd.

Headquartered in Houjie, Dongguan, LiNa owns a 30 000 m² smart manufacturing base and has specialized in rubber/plastic mixing & extrusion equipment for over 20 years. The company is a National High-Tech Enterprise and a Guangdong Contract-Abiding & Creditworthy Enterprise, with 80+ patents and ISO 9001 / CE / UL certifications. Products are exported to 40+ countries and regions. LiNa provides turnkey plant solutions and 24-hour after-sales service across China.