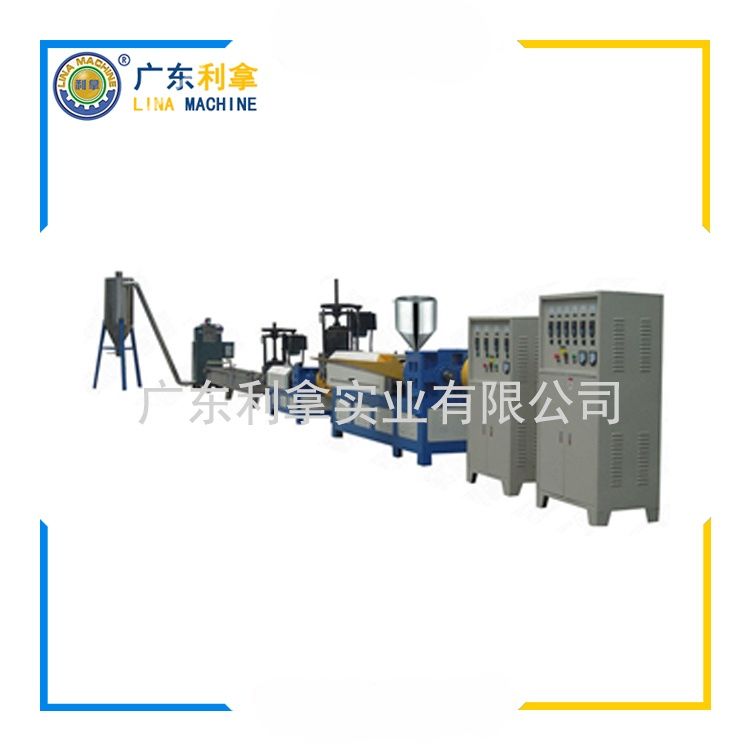

The Double-Stage Pelletizing Unit Production Line

The Double-Stage Pelletizing Unit is a crucial component in the pharmaceutical and food processing industries. It plays a significant role in the production of solid dosage forms, such as tablets, capsules, and granules. This article will provide an overview of the Double-Stage Pelletizing Unit production line, including its design, operation, and benefits.

Design:

The Double-Stage Pelletizing Unit consists of two main stages: the granulator and the pelletizer. The granulator is responsible for crushing the raw material into smaller particles, while the pelletizer is used to shape the particles into the desired size and shape. The final product is then dried and sieved to remove any impurities before being packaged and shipped to customers.

Operation:

The Double-Stage Pelletizing Unit operates by feeding the raw material into the granulator, which uses high-speed rotating blades to crush the material into small pieces. These small pieces are then transferred to the pelletizer, where they are further crushed and shaped into the desired size and shape. The resulting pellets are then dried and cooled before being sieved to remove any remaining impurities.

Benefits:

The Double-Stage Pelletizing Unit has several advantages over traditional methods of producing solid dosage forms. Firstly, it allows for more precise control over the particle size and shape, which can improve the quality of the final product. Secondly, it reduces waste by efficiently converting the raw material into usable pellets, rather than leaving it as scrap. Finally, it saves time and labor costs by eliminating the need for manual labor in the granulation process.

1. Double-Stage Pelletizing Unit

2. Granulator

3. Pelletizer

4. Solid Dosage Forms

5. Quality Control

The Double-Stage Pelletizing Unit is a highly efficient and precise method of producing solid dosage forms that ensures consistent quality and reduced waste. With its advanced design and operational capabilities, this unit offers significant benefits over traditional methods, making it an essential tool in the pharmaceutical and food processing industries.