Understanding the EVA, TPR, and PVC Pulping Production Lines

In the realm of polymer processing, the production line plays a crucial role in transforming raw materials into finished products. Among the three most common types of plastics - EVA (Ethylene Vinyl Acetate), TPR (Thermoplastic Rubber), and PVC (Polyvinyl Chloride) - each has its own unique characteristics that make it stand out from the rest. In this article, we will delve into the details of these three important production lines, highlighting their key features and how they contribute to the overall process.

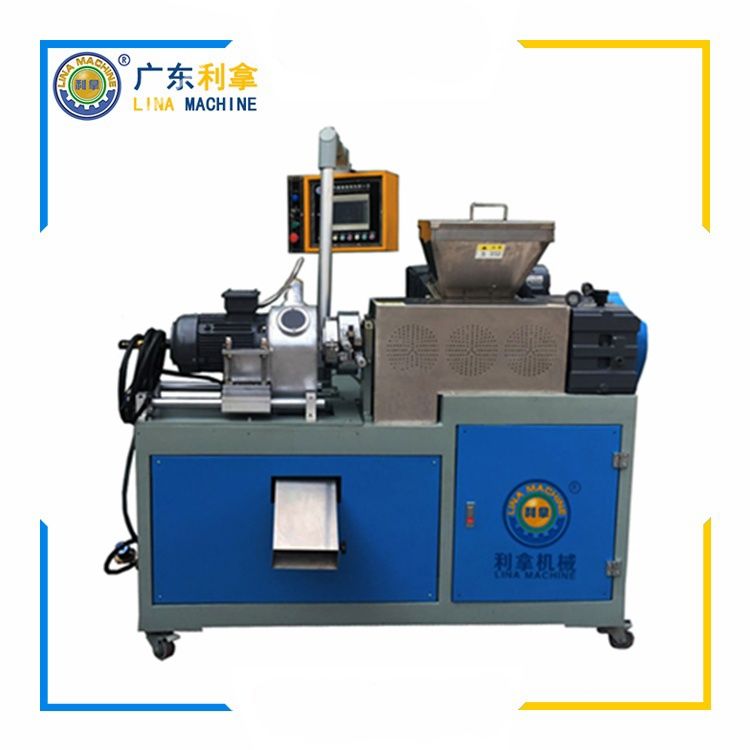

Firstly, let's explore the EVA production line. This line is designed to convert ethylene and vinyl acetate into EVA, a versatile thermoplastic material with excellent flexibility and tear resistance. The EVA production line consists of several stages, including feedstock preparation, reactor setup, and final product collection. During the process, the raw materials undergo a series of chemical reactions that result in the formation of EVA. The key factors that influence the efficiency and quality of the EVA production line include the choice of catalyst, temperature control, and the purity of the raw materials.

Moving on to the TPR production line, this line is specifically designed to produce thermoplastic rubber, which is used in a variety of applications such as automotive parts, toys, and packaging. The TPR production line consists of a reactor setup that allows for the melting and mixing of raw materials, followed by the addition of additives such as carbon black and stabilizers. The key components of the TPR production line include the reactor, heat exchanger, and cooling system. The effectiveness of the TPR production line depends on the quality of the raw materials and the precise control of the temperature and pressure during the reaction stage.

Finally, let's examine the PVC production line. This line is responsible for converting polyvinyl chloride into various shapes and sizes, making it an essential component in many industries such as construction, transportation, and packaging. The PVC production line involves several stages, including raw material preparation, melting and extrusion, and shaping and cooling. The key factors that determine the efficiency and quality of the PVC production line include the selection of appropriate equipment, the temperature control during the extrusion process, and the precision of the molding technique.

In conclusion, understanding the different production lines involved in the manufacture of EVA, TPR, and PVC is crucial for anyone working in the field of polymer processing. Each production line has its unique features and challenges, but by mastering them, companies can produce high-quality products that meet the needs of their customers. As technology continues to advance, the development of more efficient and sustainable production lines will become increasingly important for businesses looking to stay competitive in today's market.