Understanding the Forced Feed Extruder

The forced feed extruder is a crucial piece of equipment in the food processing industry, particularly in the production of high-quality plastics and other polymeric materials. This machine uses a continuous force to push the raw material through a die, resulting in a uniform and consistent product. In this article, we will explore the working principles, advantages, and applications of this machine.

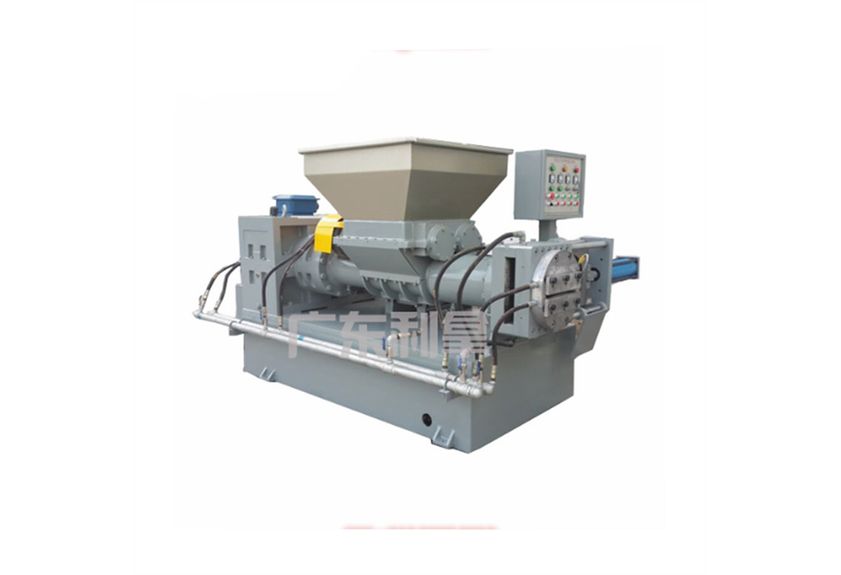

Firstly, let's understand the working principle of the forced feed extruder. The machine consists of a hopper, screw, die, and barrel. The raw material is fed into the hopper, which is then transported to the screw by the motor. As the screw rotates, it forces the material through the die, which is designed to produce a specific shape or size. The barrel serves as a container for the extruded material, which is then collected and packaged for further use.

One of the main advantages of the forced feed extruder is its ability to produce high-quality products with consistent properties. The screw design ensures that the material is evenly distributed throughout the barrel, preventing clogging and ensuring a uniform flow rate. Additionally, the die can be easily adjusted to produce different shapes and sizes, making it versatile for a wide range of applications.

In terms of applications, the forced feed extruder is used in industries such as plastics, rubber, and textiles. It is particularly useful in the production of films, pipes, and other flexible materials, which are essential components in many consumer products. For example, food packaging often uses extruded plastics, while medical devices require high-quality silicone tubing.

Another important aspect of the forced feed extruder is its energy efficiency. Unlike some other types of machinery, which require constant power to maintain their operation, the extruder can operate at a lower speed and still produce consistent results. This makes it an ideal choice for industrial settings where energy consumption is a concern.

In conclusion, the forced feed extruder is a powerful tool in the food processing industry, capable of producing high-quality products with consistent properties. Its ability to produce different shapes and sizes, coupled with its energy efficiency, make it a valuable asset for businesses looking to improve their manufacturing processes. By understanding the working principles and advantages of this machine, manufacturers can optimize their operations and achieve greater success in the competitive market.