Flexible Plastic Pellet Production Line

The flexible plastic pellet production line is an essential tool in the plastic industry, enabling manufacturers to produce high-quality plastic pellets with consistent quality and efficiency. This article will provide a detailed introduction to this production line, including its design, features, and application scenarios.

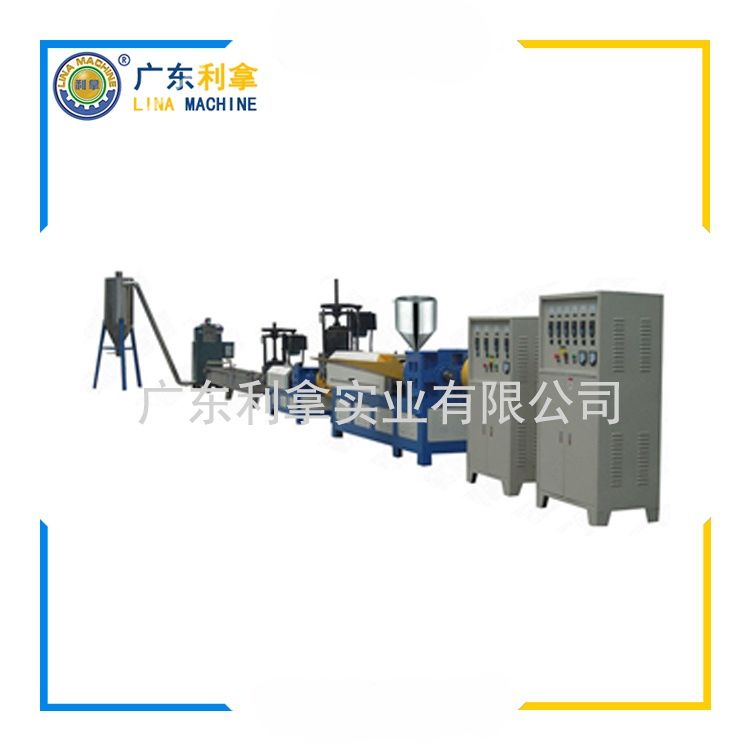

The flexible plastic pellet production line is designed to meet the needs of various plastic products, such as toys, packaging materials, and automotive parts. It consists of several key components, including a feeder system, melting and mixing equipment, cooling and granulation system, and packaging system. The feeder system is responsible for feeding raw plastic material into the melting and mixing equipment, while the melting and mixing equipment heats and mixes the material to form a uniform melt. The cooling and granulation system then cools the melt and granulate it into small pellets, while the packaging system packages the pellets into individual units for storage or transportation.

One of the key advantages of the flexible plastic pellet production line is its flexibility. It can be easily adjusted to meet the specific requirements of different plastic products, allowing manufacturers to produce customized products quickly and efficiently. Additionally, the production line is highly automated, reducing labor costs and improving production efficiency.

In terms of features, the flexible plastic pellet production line has several notable features. Firstly, it uses advanced technology to ensure that the material is evenly mixed and heated, producing high-quality plastic pellets. Secondly, the production line is equipped with various sensors and control systems, allowing operators to monitor and adjust the process in real-time, ensuring consistent product quality. Finally, the production line is designed to be easy to maintain and repair, reducing downtime and maintenance costs.

Application scenarios for the flexible plastic pellet production line are diverse. For example, it can be used in the manufacturing of plastic toys, such as teddy bears and dolls, where high-quality plastic pellets are needed for molding and shaping. In the packaging industry, the flexible plastic pellet production line can be used to produce plastic bags, bottles, and other packaging materials, ensuring that they meet environmental standards and consumer demands. Additionally, the production line can also be used in the automotive industry to produce plastic parts, such as fuel tanks and engine covers, which require high-quality plastic pellets for molding and assembly.

In conclusion, the flexible plastic pellet production line is an essential tool in the plastic industry, providing manufacturers with a reliable and efficient way to produce high-quality plastic pellets. With its advanced technology, flexible design, and wide range of applications, it is expected to continue playing an important role in the future development of the plastic industry.