The Four-Roll Mill: A Revolutionary Tool for Rubber and Plastics Manufacturing

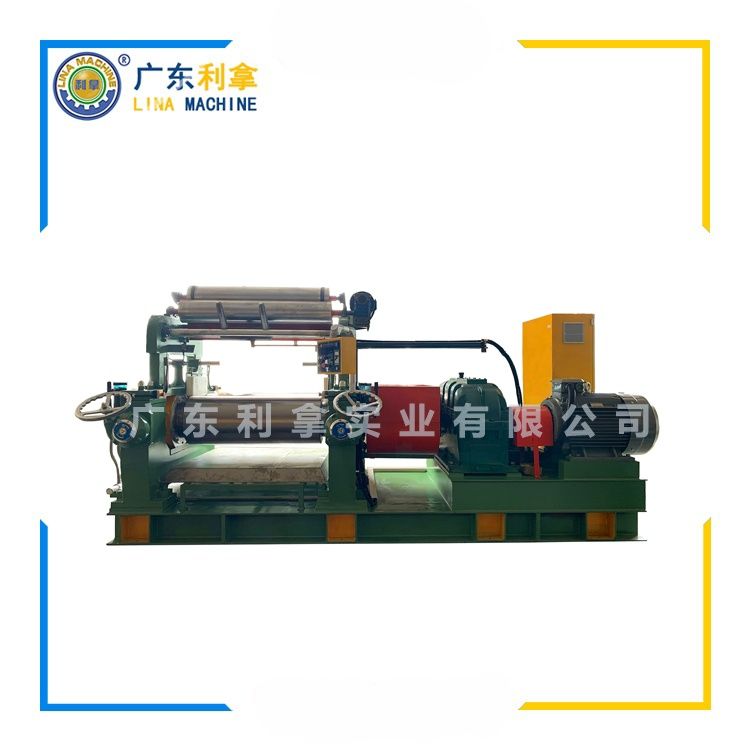

The four-roll mill is a crucial piece of equipment in the rubber and plastics manufacturing industry. It is an essential tool that allows for the processing of raw materials into finished products with high efficiency and consistency. This machine uses four rollers to mix, knead, and extrude rubber and plastic compounds, resulting in a uniform texture and quality.

One of the key features of the four-roll mill is its ability to handle a wide range of materials, including natural and synthetic rubbers, plastics, and other polymers. This makes it versatile and suitable for a variety of applications, from automotive parts to packaging materials.

In addition to its versatility, the four-roll mill also has several advantages over traditional methods of processing. For example, it can produce more consistent results with less waste, which saves time and money. Additionally, the use of advanced technology in this machine allows for precise control over the temperature and pressure during processing, ensuring optimal results every time.

Overall, the four-roll mill is a powerful tool that has revolutionized the way we manufacture rubber and plastic products. Its versatility, efficiency, and precision make it an essential piece of equipment for any production facility looking to improve their bottom line.