The Flexible Plastic Pellet Production Line

The flexible plastic pellet production line is a crucial part of the plastic processing industry. It involves the conversion of raw plastic materials into pellets, which are then used in various applications such as packaging, construction, and automotive industries. This article will provide an overview of the key components of a flexible plastic pellet production line, including the feeder system, melting unit, cooling unit, granulation unit, and packaging unit.

The feeder system is responsible for feeding the raw plastic material into the melting unit. There are several types of feeders available, including screw feeders, hopper feeders, and belt conveyors. The choice of feeder system depends on the specific requirements of the application and the type of plastic being processed.

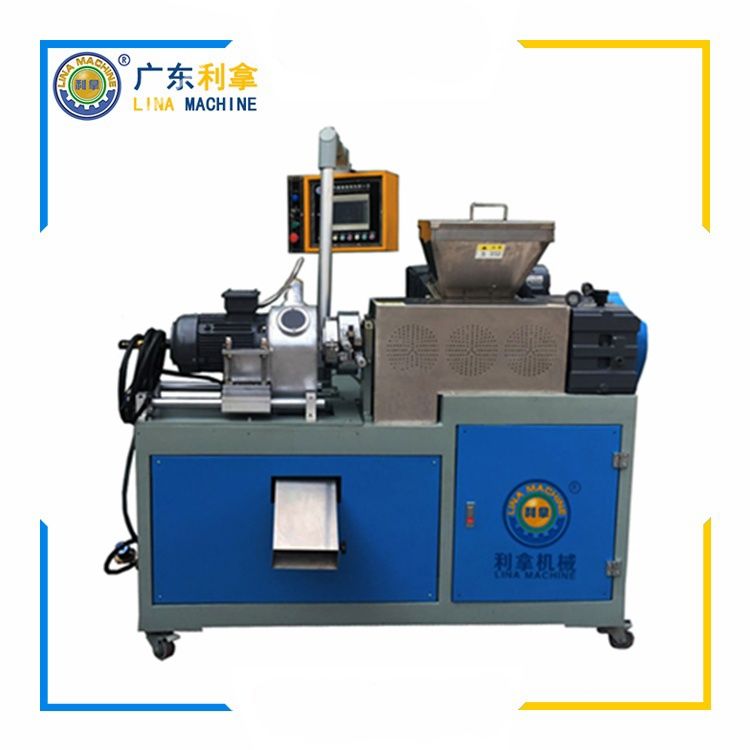

The melting unit is where the raw plastic material is heated to a high temperature and melted. The melting process is critical in ensuring that the pellets produced have a uniform and consistent quality. There are different types of melting units available, including rotary kiln, fluidized bed, and extruder. The choice of melting unit depends on the specific requirements of the application and the type of plastic being processed.

The cooling unit is responsible for cooling the molten plastic down to a suitable temperature before it enters the granulation unit. The cooling process is essential in preventing the formation of undesirable impurities and maintaining the consistency of the pellets. There are different types of cooling units available, including air coolers, water spray coolers, and forced draft coolers. The choice of cooling unit depends on the specific requirements of the application and the type of plastic being processed.

The granulation unit is where the molten plastic is cooled and granulated into pellets. The granulation process is critical in ensuring that the pellets produced have a uniform and consistent size and shape. There are different types of granulation units available, including rotary drum granulator, hammer mill granulator, and twin-screw granulator. The choice of granulation unit depends on the specific requirements of the application and the type of plastic being processed.

Finally, the packaging unit is responsible for collecting and packaging the pellets produced. There are different types of packaging units available, including palletizers, bagsters, and bale makers. The choice of packaging unit depends on the specific requirements of the application and the type of plastic being processed.

1. Flexible Plastic Pellet Production Line

2. Feeder System

3. Melting Unit

4. Cooling Unit

5. Granulation Unit

6. Packaging Unit

7. Plastic Processing Industry

8. Rotary Kiln

9. Fluidized Bed

10. Extruder

11. Air Cooler

12. Water Spray Cooler

13. Forced Draft Cooler

14. Rotary Drum Granulator

15. Hammer Mill Granulator

16. Twin-Screw Granulator

17. Palletizers

18. Baggers

19. Bale Makers

The "Flexible Plastic Pellet Production Line" is an essential component of the plastic processing industry. It involves the conversion of raw plastic materials into pellets, which are then used in various applications such as packaging, construction, and automotive industries. The production line consists of several key components, including the feeder system, melting unit, cooling unit, granulation unit, and packaging unit. Each component plays a critical role in ensuring that the pellets produced have a uniform and consistent quality. The flexible plastic pellet production line is highly efficient and can handle a wide range of plastic materials, making it an ideal solution for businesses looking to improve their production processes.