The Integration of Polymer and Plastic in Compounding and Granulation Production Lines

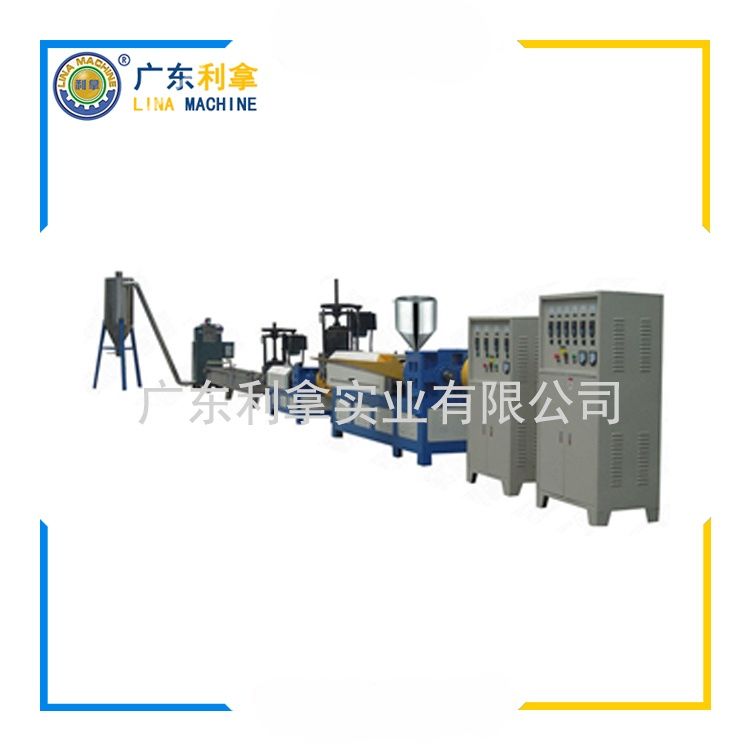

The production line for compounding and granulation is a crucial step in the manufacturing process of various polymer products. It involves the blending of two or more types of polymers to create a new material, which is then granulated into pellets for further processing. This process not only enhances the properties of the final product but also reduces waste and improves efficiency. In this article, we will explore the different components of the compounding and granulation production line, their functions, and how they work together to produce high-quality polymer products.

The first component of the production line is the compounding unit. This unit is responsible for mixing the two or more types of polymers that will be used in the granulation process. The compounding unit uses a variety of techniques, including mechanical mixing, heat treatment, and chemical reactions, to achieve a uniform distribution of the polymers throughout the mixture. The resulting compound is then fed to the granulation unit, where it is granulated into pellets.

The granulation unit is another critical component of the production line. It takes the compounded material and granulate it into small pellets that can be easily handled and transported. The granulation process involves several steps, including compression, extrusion, and cooling. During these steps, the pellets are formed from the compounded material and have a uniform size and shape. The granulation unit also has a cooling system that helps to solidify the pellets and prevent them from deforming during transportation.

The final component of the production line is the packaging unit. This unit is responsible for packaging the granulated material in appropriate containers for storage and shipping. The packaging process involves sealing the container with adhesive tape or other materials to ensure that the material remains fresh and protected from moisture and dust.

In conclusion, the compounding and granulation production line is an essential part of the polymer manufacturing process. By combining the functions of the compounding unit, granulation unit, and packaging unit, manufacturers can produce high-quality polymer products with improved properties and reduced waste. As technology continues to advance, the production line will continue to evolve to meet the needs of the industry and provide even better results.