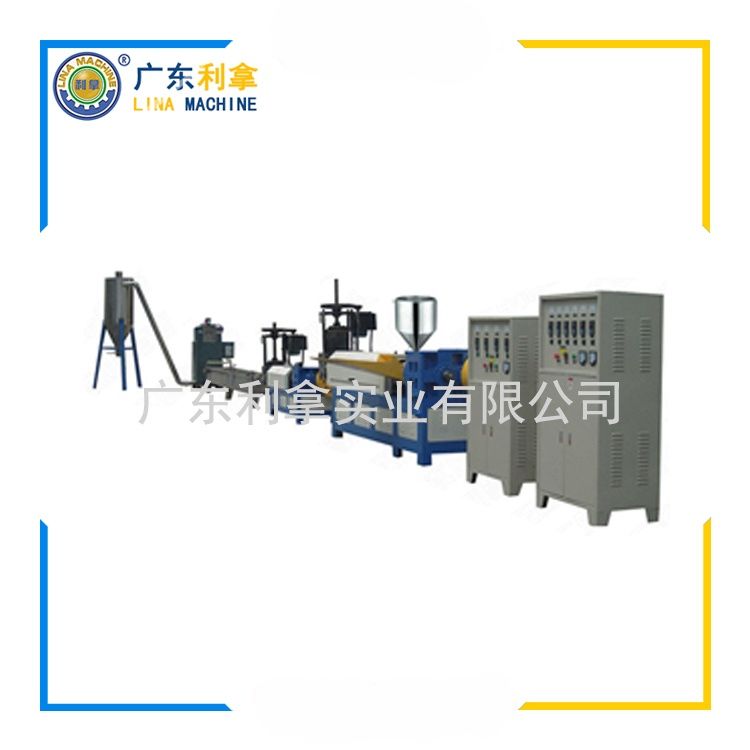

Underwater Cutting Pellet Production Line

The underwater cutting pellet production line is a crucial component in the pharmaceutical industry, particularly in the manufacturing of solid dosage forms. This article will provide an overview of the key components and functions of this line, as well as its significance in the production process.

The underwater cutting pellet production line consists of several key stages, including preparation, cutting, mixing, and granulation. In the preparation stage, raw materials such as excipients, fillers, and binders are weighed and mixed together to form a uniform mixture. The cutting stage involves feeding the mixture into a die-cutting machine, which cuts it into pellets with precise dimensions. The mixing stage follows, where the pellets are further blended with lubricants and other additives to improve their physical properties. Finally, the granulation stage involves shaping the pellets into desired shapes using a granulator.

The underwater cutting pellet production line plays a critical role in the pharmaceutical industry by ensuring that solid dosage forms are produced with high precision and consistency. By controlling the size, shape, and surface characteristics of the pellets, manufacturers can produce drugs that are more effective and easier to administer. Additionally, the use of underwater cutting technology allows for the integration of automation and robotics, reducing labor costs and improving efficiency.

In conclusion, the underwater cutting pellet production line is a vital component of the pharmaceutical industry, providing manufacturers with the tools they need to produce solid dosage forms with high precision and consistency. Its ability to integrate automation and robotics further enhances its effectiveness and efficiency, making it an essential tool in the modern pharmaceutical landscape.