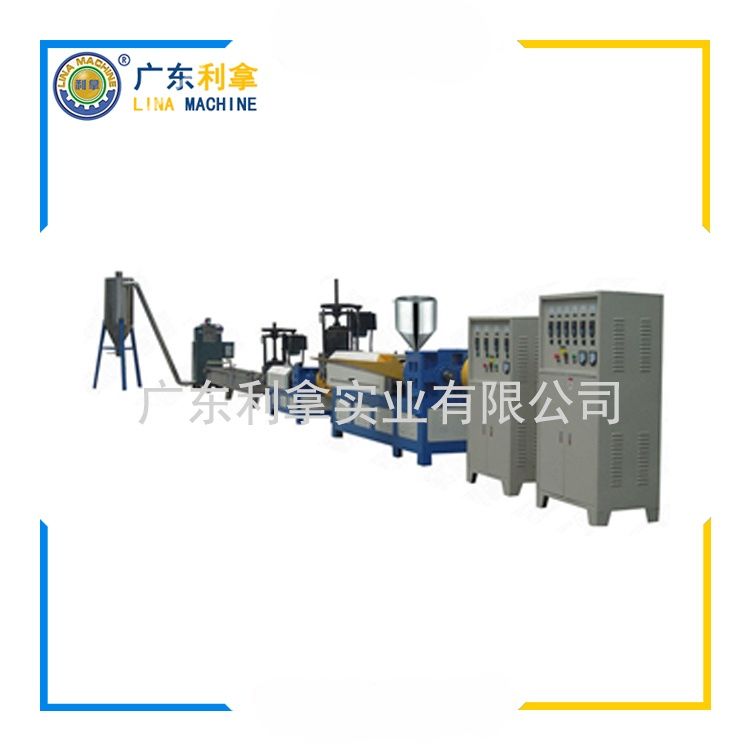

The Double-Screw Extrusion Spraying Machine

The double-screw extruder is a versatile and efficient tool in the polymer processing industry. It is widely used for producing various types of plastic products, such as pellets, films, and injection molded parts. This machine is designed to mix and melt thermoplastics, resins, and other materials into a uniform, high-quality feedstock. The process involves two rotating screws that push the material through the extruder barrel, where it is heated and mixed with other ingredients. The resulting mixture is then forced out of the end of the extruder, often through a die or nozzle, to form the desired shape and size of the final product.

One of the key features of the double-screw extruder is its ability to produce high-quality feedstocks with consistent properties. This is achieved through precise control of temperature, pressure, and screw design. By adjusting these parameters, manufacturers can tailor the feedstock to meet specific requirements, such as melt flow rate, viscosity, and crystallinity. This flexibility makes the double-screw extruder an ideal choice for producing a wide range of products, from simple household items to complex industrial components.

In addition to its technical advantages, the double-screw extruder also has a strong impact on the environment. By using renewable energy sources and implementing energy-efficient designs, manufacturers can reduce their carbon footprint and minimize waste. This not only helps to protect the planet but also contributes to economic sustainability by reducing costs associated with raw material transportation and processing.

1. Double-Screw Extruder

2. Plastic Processing

3. Feedstock Production

4. High-Quality Product

5. Environmentally Friendly Manufacturing

The double-screw extruder is a critical component in the production of high-quality plastic products. Its ability to produce consistent feedstocks with tailored properties makes it an essential tool for manufacturers looking to optimize their processes while minimizing environmental impact. With its advanced technology and eco-friendly features, this machine is poised to become a dominant force in the global plastic industry.