PTFE压延机:现代工业中的关键设备

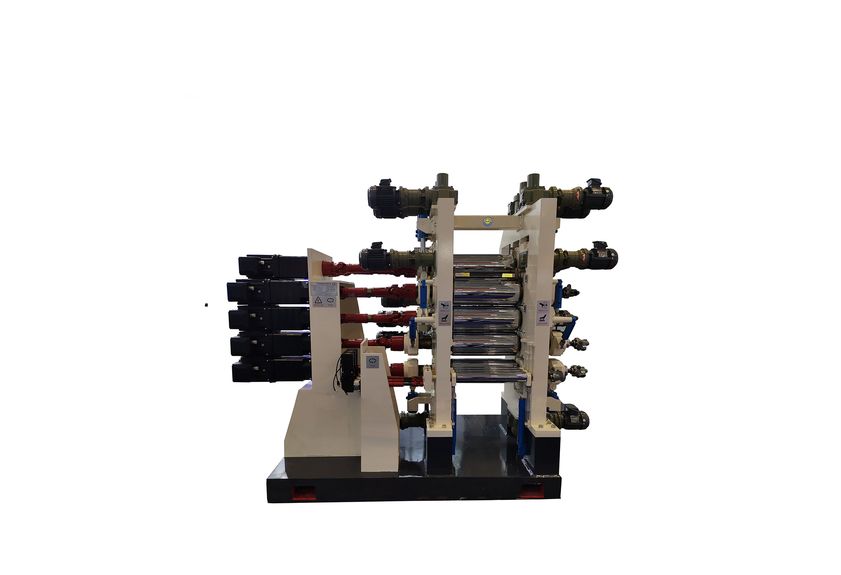

The PTFE (Polytetrafluoroethylene) extrusion machine is a crucial piece of equipment in the modern industrial world. It is used to produce high-quality PTFE products, such as hoses, seals, and filters, which are widely used in various industries. The PTFE extruder is designed to handle PTFE material with high temperature and pressure, making it ideal for applications where durability and resistance to chemicals are essential.

One of the main features of the PTFE extruder is its ability to process large volumes of PTFE material quickly and efficiently. This is achieved through the use of advanced technology and sophisticated machinery that allows for precise control over the extrusion process. The machine also features a variety of features that make it easy to operate and maintain, including automatic temperature control, pressure adjustment, and safety features such as emergency stop buttons.

In addition to its technical advantages, the PTFE extruder has many practical applications in the industry. For example, it can be used to produce hoses for transportation systems, seals for industrial equipment, and filters for water treatment plants. These products are highly resistant to wear and tear, making them ideal for use in harsh environments where regular maintenance is difficult or expensive.

Overall, the PTFE extruder is an essential tool for any industrial operation that requires the production of high-quality PTFE products. Its advanced technology and versatile capabilities make it a valuable asset in the manufacturing industry, helping companies to meet their production needs while minimizing costs and improving efficiency.