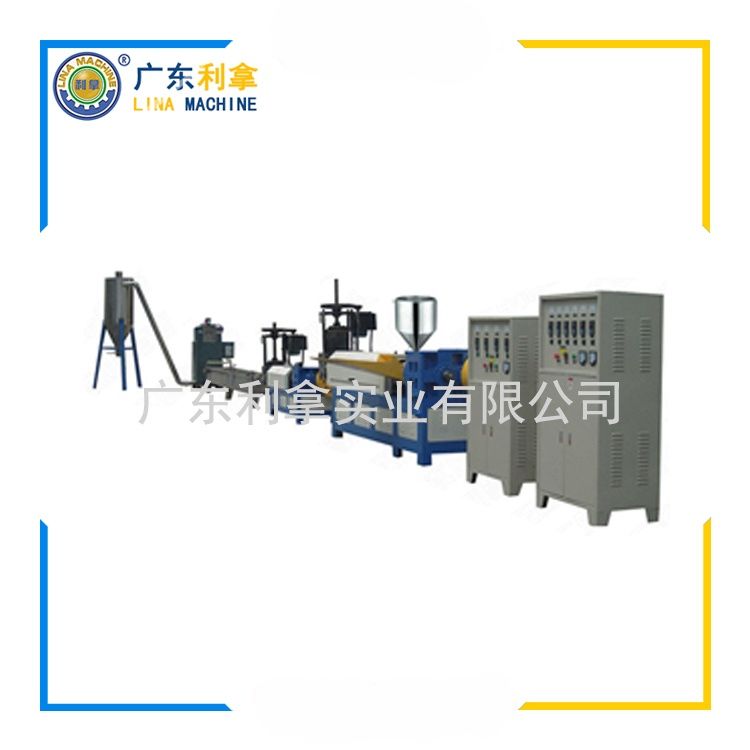

The Low-Smoke and Zero-Halogen Pelletizing Machine

The low-smoke and zero-halogen pelletizing machine is a revolutionary innovation in the field of polymer processing. This innovative technology has revolutionized the way plastics are made, making it possible to produce high-quality products with minimal environmental impact.

At its core, this machine uses a combination of advanced materials and processes to create pellets that are both low-smoke and free from harmful chemicals. By using a unique combination of ingredients, the machine can produce pellets that are free from halogen compounds, which are commonly found in traditional plastics.

This technology has several benefits for both the environment and the end user. Firstly, it reduces the amount of smoke produced during the manufacturing process, which can be harmful to human health and the environment. Secondly, it eliminates the use of harmful chemicals, which can have negative effects on the environment and human health.

In addition to these environmental benefits, the low-smoke and zero-halogen pelletizing machine also produces pellets that are of high quality and consistent in size. This means that end users can rely on consistent product quality, which is essential for many industries, such as food packaging and medical equipment.

Overall, the low-smoke and zero-halogen pelletizing machine represents a significant advancement in the field of polymer processing. It has the potential to transform the way we make plastics, while also reducing our impact on the environment. As more companies adopt this technology, we can expect to see even greater improvements in the future.