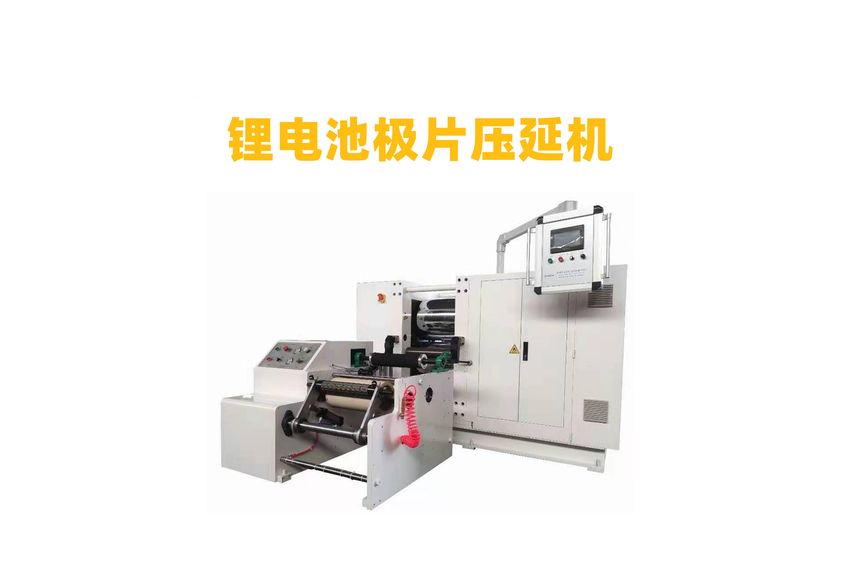

Advanced Absorber Material Rolling Machine

The development of advanced absorber materials has been a key focus in the field of acoustic engineering. One of the most innovative advancements in this area is the use of roll-forming machines to produce high-quality absorber materials. These machines are designed to process various types of absorber materials, including metal foams, polymers, and composites, into uniform and consistent shapes.

One of the main advantages of using roll-forming machines for absorber material production is their ability to produce complex shapes with high precision and accuracy. This allows for better acoustic performance and efficiency in applications such as soundproofing and vibration control. Additionally, these machines can handle a wide range of materials, making them versatile and adaptable to different applications.

Another significant benefit of roll-forming machines is their ability to produce high-quality absorber materials at a faster rate than traditional methods. This is achieved through the use of advanced technology and automation systems that ensure consistency and repeatability in the manufacturing process. As a result, manufacturers can produce larger volumes of absorber materials more efficiently and cost-effectively.

In conclusion, the use of roll-forming machines for absorber material production represents a significant advancement in the field of acoustic engineering. These machines offer numerous benefits, including improved precision, versatility, and efficiency, which make them an essential tool for manufacturers looking to optimize their acoustic performance.