The Five-Roll Rolling Press: A Revolutionary Tool for Metal Forming

The five-roll rolling press is a highly sophisticated piece of machinery designed to perform metal forming operations with precision and efficiency. This machine has become an indispensable tool in the manufacturing industry, particularly in the automotive, aerospace, and construction sectors. Its unique design and advanced technology have made it one of the most versatile and powerful tools available today.

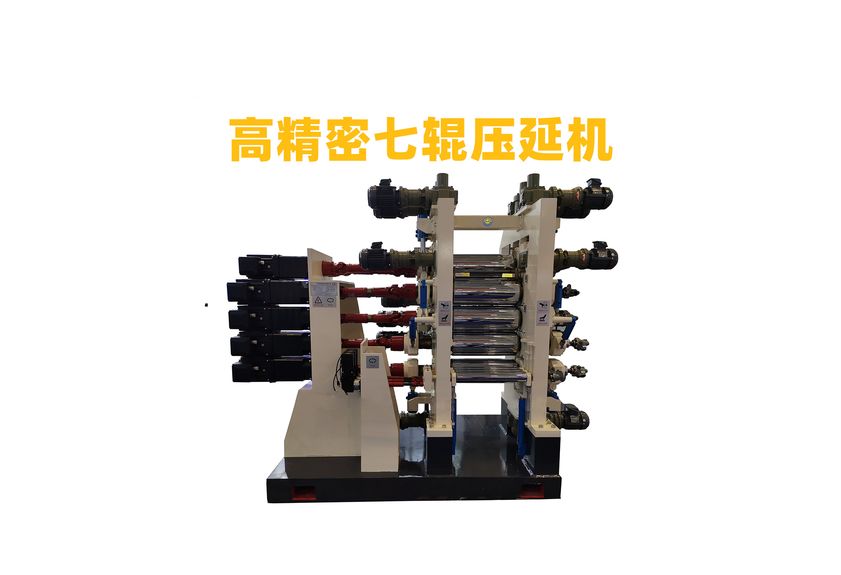

At its core, the five-roll rolling press consists of five rollers that are arranged in a specific pattern to achieve the desired shape of the metal sheet being processed. These rollers are precisely engineered to ensure uniform pressure and consistent thickness throughout the entire length of the sheet. The machine's ability to handle a wide range of materials, including steel, aluminum, and copper, makes it highly adaptable to different applications.

One of the key features of the five-roll rolling press is its ability to produce high-quality products with minimal waste. By using advanced control systems and sensors, the machine can detect any defects or irregularities in the material being processed and adjust its settings accordingly. This ensures that each product produced is of the highest quality possible.

Another advantage of the five-roll rolling press is its speed and productivity. With its fast processing capabilities, this machine can turn out large volumes of metal sheets quickly and efficiently. This not only saves time but also reduces labor costs, making it a cost-effective investment for businesses looking to improve their production efficiency.

In addition to its technical advantages, the five-roll rolling press also boasts a sleek and modern design that enhances its appearance in any workshop or factory setting. Its compact size and lightweight construction make it easy to move around and set up, making it ideal for use in small or medium-sized enterprises.

Overall, the five-roll rolling press is a game-changer in the world of metal forming. Its advanced technology, high-quality products, and efficient production capabilities have made it a favorite among professionals in the manufacturing industry. As technology continues to advance, we can expect even more innovative designs and features from this revolutionary tool, ensuring that it remains at the forefront of metal forming innovation for years to come.