Title: Understanding the Impor...

Title: Understanding the Importance of Cable and Wires Extrusion Molding Machines

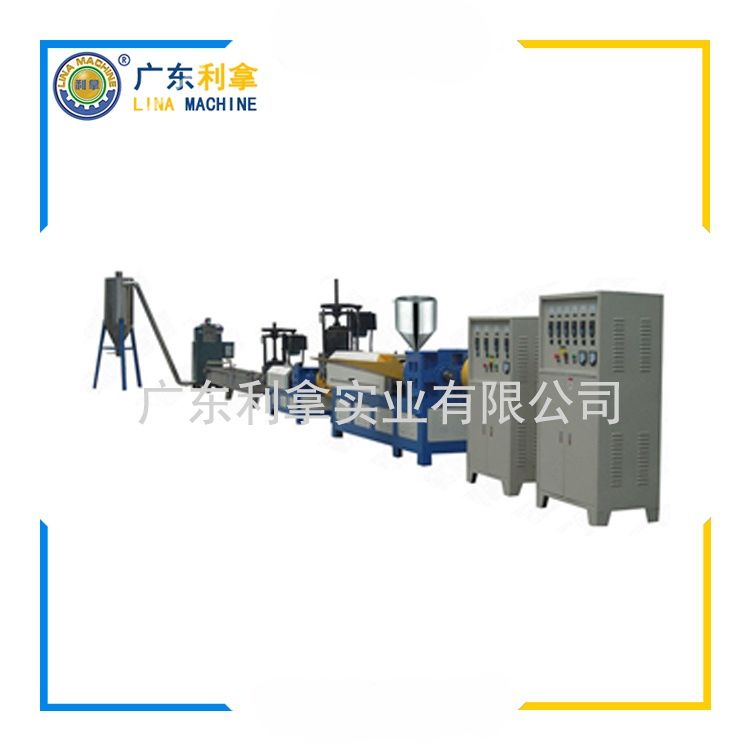

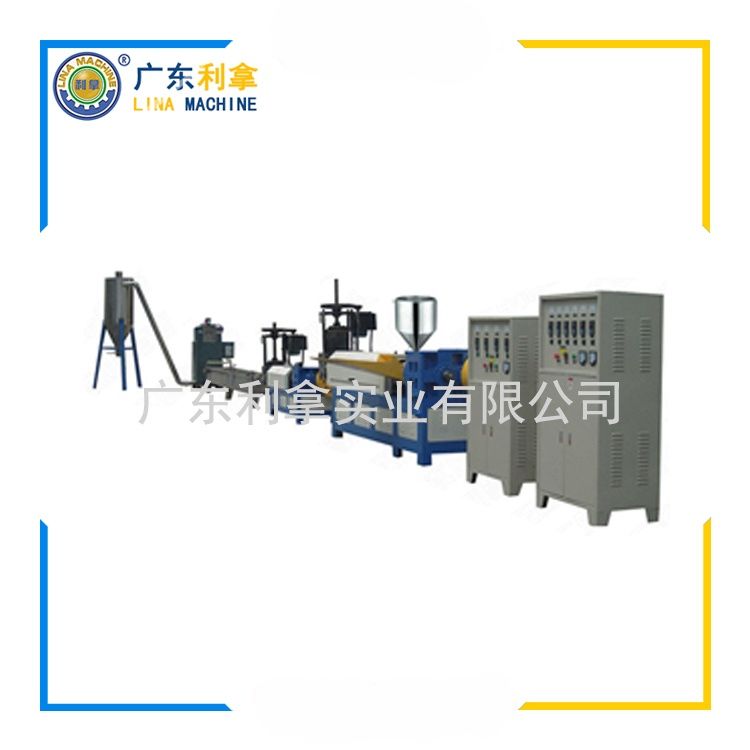

In the world of industrial production, precision and efficiency are paramount. One such critical component that ensures these standards is the cable and wire extrusion molding machine. This specialized machinery plays a vital role in the manufacturing process of electrical wiring, cables, and other conductive materials. Let's delve into the intricacies of this essential piece of equipment.

What is a Cable and Wires Extrusion Molding Machine?

A cable and wire extrusion molding machine is a high-tech device designed to transform raw materials into finished products. It is a versatile tool that can be used for various applications, including the manufacture of power cables, data cables, and even medical wires. The machine works by using high-pressure air or water to force molten plastic or rubber through a die, which then solidifies to form the desired shape.

Why is it Crucial for Industrial Production?

The importance of cable and wire extrusion molding machines cannot be overstated. They are essential for industries that require precise control over their product specifications, such as automotive, electronics, and construction. By using these machines, manufacturers can produce cables and wires with consistent quality, reduced waste, and increased productivity.

How Does It Work?

The process begins with the raw material being fed into the machine. This material is then melted and forced through a die at high pressure. As the molten material exits the die, it solidifies and forms the final product. The machine has several features that enhance its efficiency, such as adjustable dies, temperature control, and automated feeding systems.

Key Features of Cable and Wires Extrusion Molding Machines

1. High-Pressure Dies: These dies ensure that the molten material is forced through with sufficient force to achieve the desired shape and size.

2. Temperature Control: Proper temperature control is crucial for ensuring the consistency of the product's properties.

3. Automation: Many modern extrusion molding machines are equipped with automation features, allowing for faster and more accurate production.

4. Energy Efficiency: Some models use energy-efficient technologies like LED lighting and variable speed drives to reduce operational costs.

5. Safety Features: To protect workers from potential hazards, many extrusion molding machines come equipped with safety features like automatic shutoff mechanisms and emergency stop buttons.

Benefits of Using Cable and Wires Extrusion Molding Machines

Using these machines offers numerous benefits to both manufacturers and consumers. For manufacturers, it allows them to produce high-quality products with reduced labor costs and increased efficiency. For consumers, it means better-performing electrical and communication systems that are safer and more reliable.

In conclusion, cable and wire extrusion molding machines are an essential part of the industrial production landscape. Their ability to produce high-quality products with consistent specifications makes them indispensable for industries across multiple sectors. As technology continues to advance, we can expect these machines to become even more sophisticated, offering even greater benefits to the global economy.