The Art of Rubber Masterbatch Pelletizing Machinery

In the realm of polymer processing, the art of masterbatch pelletizing is a crucial step in the production process. At its core, this process involves the creation of uniformly sized and shaped particles from a mixture of polymers, additives, and other components. The rubber masterbatch pelletizing machine plays a pivotal role in this process, as it ensures that the final product meets the desired specifications and quality standards.

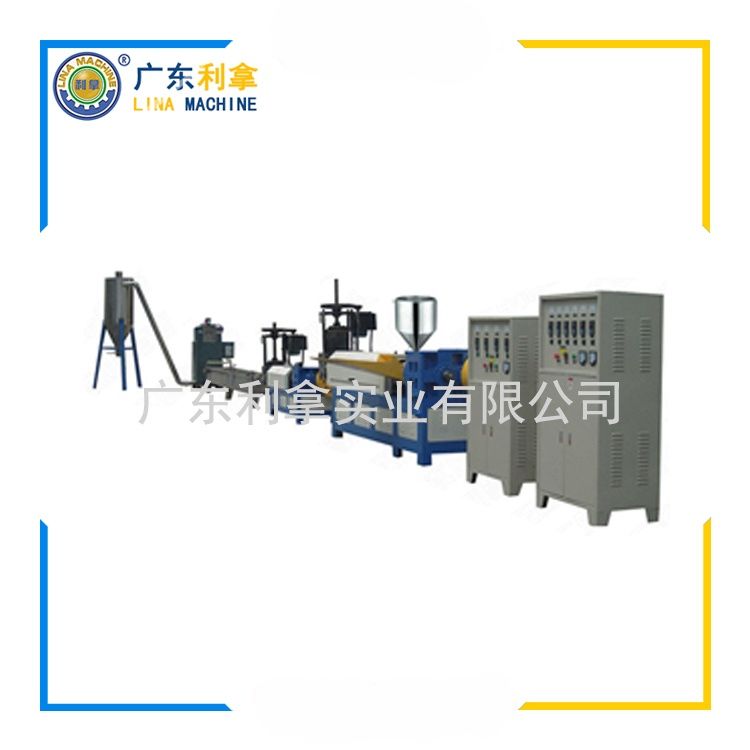

At its core, the rubber masterbatch pelletizing machine is a sophisticated piece of equipment designed to handle the complexities of the process. It consists of several key components, including a hopper, a screw extruder, a cooling system, and a granulator. The hopper collects the raw materials, while the screw extruder mixes them thoroughly. The cooling system then cools the molten material down to the appropriate temperature for granulation. Finally, the granulator processes the material into uniformly sized pellets.

The importance of the rubber masterbatch pelletizing machine cannot be overstated. Without it, the production process would be significantly hindered, resulting in subpar quality products. The machine's ability to control the temperature, pressure, and flow rate of the material ensures that the final product meets the required specifications. Additionally, the machine's precision in size measurement and shape control allows for consistent results every time.

One of the most significant advantages of the rubber masterbatch pelletizing machine is its ability to produce high-quality products at a faster rate. By using advanced technology and automation, the machine can process large quantities of material quickly and efficiently. This not only reduces labor costs but also minimizes waste and improves overall efficiency.

Another important consideration when selecting a rubber masterbatch pelletizing machine is its compatibility with different types of raw materials. The machine should be able to handle a wide range of polymers, additives, and other components without any issues. This ensures that the final product remains consistent and reliable across different applications.

In conclusion, the rubber masterbatch pelletizing machine is an essential tool in the production process. Its ability to create uniformly sized and shaped particles from a mixture of polymers, additives, and other components ensures that the final product meets the desired specifications and quality standards. With its advanced technology and automation capabilities, the machine can process large quantities of material quickly and efficiently, minimizing labor costs and improving overall efficiency.