The Development and Application of Hydrogen Fuel Cell Bipolar Plate Rolling Machine Production Line

The hydrogen fuel cell, a promising technology for clean energy, has attracted widespread attention in recent years. One of the key components of a hydrogen fuel cell is the bipolar plate, which plays a crucial role in conducting electricity between the cathode and anode. To meet the increasing demand for high-quality bipolar plates, the development of a dedicated production line for hydrogen fuel cell bipolar plates has become an essential step. This article will introduce the latest advancements in the production line for hydrogen fuel cell bipolar plates, including the design of the rolling machine, the selection of materials, and the quality control measures.

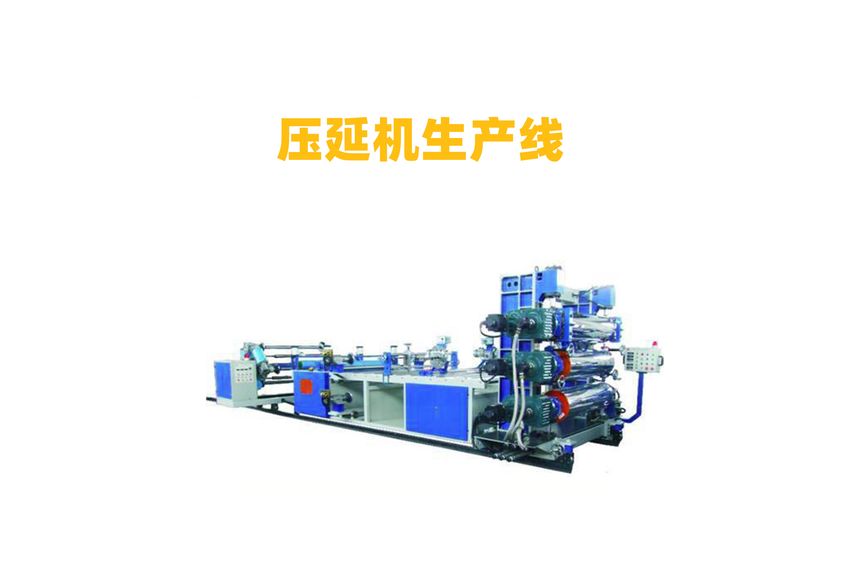

The design of the rolling machine is crucial to ensuring the precision and consistency of bipolar plates. Modern bipolar plate rolling machines are equipped with advanced CNC (Computer Numerical Control) systems that can precisely control the movement of the rolls and adjust the thickness of the bipolar plates. The machine also features automated feeding systems, which ensure that the material is evenly fed into the rolls and prevent any defects from being introduced during the process. Additionally, the machine is equipped with sensors that monitor the temperature and pressure of the material during the rolling process, allowing for real-time adjustments to optimize the quality of the bipolar plates.

When selecting materials for the bipolar plates, it is important to consider both mechanical and electrical properties. Common materials used in bipolar plates include graphite, carbon fiber, and titanium alloys. Graphite is known for its excellent thermal conductivity and low cost, making it a popular choice for bipolar plates. Carbon fiber, on the other hand, offers superior strength and stiffness, making it ideal for applications where high mechanical stresses are present. Titanium alloys, such as Ti6Al4V, offer excellent corrosion resistance and high strength-to-weight ratio, making them suitable for use in harsh environments.

Quality control measures are essential to ensure that the bipolar plates produced meet the required standards. These measures include testing the material for physical and chemical properties, inspecting the surface finish of the bipolar plates, and verifying the thickness and dimensions of each individual piece. Additionally, regular maintenance and calibration of the rolling machine are necessary to ensure that it continues to produce high-quality bipolar plates.

In conclusion, the development of a dedicated production line for hydrogen fuel cell bipolar plates is crucial for meeting the growing demand for high-quality and reliable components. By investing in state-of-the-art equipment and implementing strict quality control measures, manufacturers can produce bipolar plates that meet or exceed industry standards. As the demand for sustainable energy continues to grow, the importance of this technology cannot be overstated.