The Evolution of Foamed Silica Gel Rolling Production Lines

In the realm of industrial manufacturing, the production line plays a pivotal role in transforming raw materials into finished products. Among these lines, the foamed silica gel rolling production line stands out for its unique contribution to the electronics and automotive industries. This article delves into the intricate details of this line, highlighting its significance in enhancing product quality and efficiency.

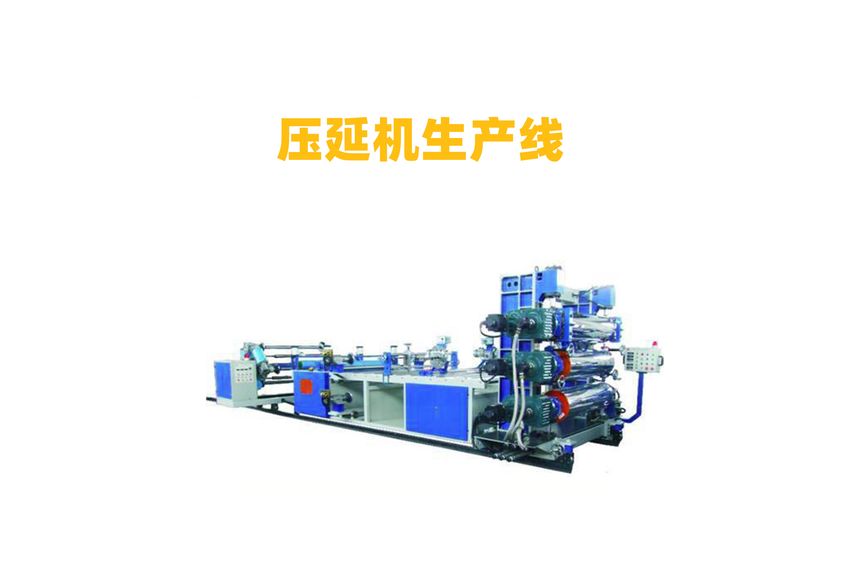

At the heart of the foamed silica gel rolling production line lies the process of foaming. This involves the introduction of air into the silicone rubber matrix, resulting in a lightweight, flexible material with excellent thermal and electrical properties. The foamed silica gel is then extruded onto a continuous roll, where it undergoes a series of processing steps such as compression molding, injection molding, and extrusion. These processes ensure that the final product meets the required specifications, including density, hardness, and flexibility.

The foamed silica gel rolling production line is designed to be highly efficient and cost-effective. By using automated machinery, the line can produce high-quality foamed silica gel at a consistent rate, reducing labor costs and minimizing waste. Additionally, the use of advanced materials and techniques ensures that the product maintains its integrity and performance over time.

One of the key benefits of the foamed silica gel rolling production line is its ability to produce customized products. With the ability to adjust the foaming process and other parameters, manufacturers can create unique shapes and sizes that meet specific customer requirements. This flexibility allows businesses to stay ahead of the competition and capture new markets.

Another advantage of the foamed silica gel rolling production line is its environmental friendliness. Unlike traditional methods, which often involve toxic chemicals and energy-intensive processes, the line uses eco-friendly materials and processes to produce sustainable products. This not only reduces the carbon footprint but also enhances the overall quality of the final product.

In conclusion, the foamed silica gel rolling production line is an essential tool for modern manufacturing. Its ability to produce high-quality, customized products while being environmentally friendly makes it a valuable asset for businesses looking to expand their reach and improve their bottom line. As technology continues to advance, we can expect to see even more innovative solutions like this one, further revolutionizing the way we manufacture and deliver products to customers worldwide.