The Role of Polymer Pelletizers in the Manufacturing Industry

Polymer pelletizers are essential equipment in the polymer processing industry, particularly in the production of high-quality polymer pellets. These machines play a crucial role in the conversion of raw polymer materials into pelletized form, which is necessary for various applications such as packaging, agriculture, and construction. In this article, we will explore the functionality, advantages, and application of polymer pelletizers.

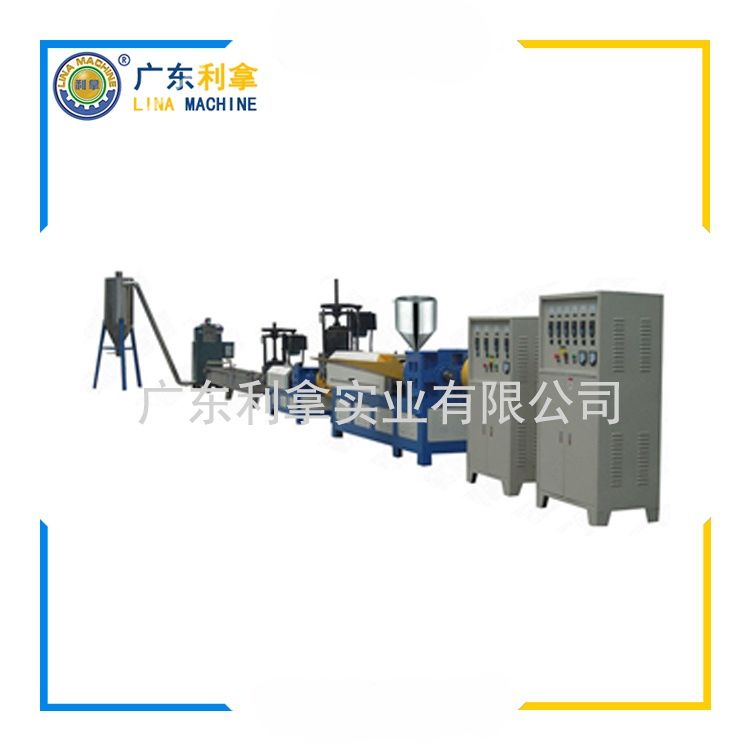

Firstly, let's understand what a polymer pelletizer is. It is a machine that uses mechanical force to break down the polymer material into small particles or pellets. This process is known as granulation. The pelletizer consists of several components, including a hopper, a rotor, and a conveyor system. The hopper holds the raw polymer material, while the rotor rotates at high speeds to crush the material into smaller pieces. The crushed material then falls onto a conveyor belt, which transports it to the desired location.

The primary function of a polymer pelletizer is to ensure that the polymer material is converted into uniform, compact pellets. This is important because pelletized polymers have better flow properties, reduced moisture absorption, and improved storage stability. Additionally, pelletized polymers are easier to handle and transport, making them more suitable for various applications.

One of the key advantages of using polymer pelletizers is their ability to produce high-quality pellets with consistent size and shape. This ensures that the final product meets the required specifications and can be used effectively in various industries. Moreover, polymer pelletizers are highly efficient, producing large quantities of pellets quickly and efficiently.

In addition to its technical benefits, the use of polymer pelletizers also has environmental advantages. By converting raw polymer materials into pellets, manufacturers can reduce waste and minimize the amount of plastic waste that ends up in landfills or oceans. This is particularly important in today's world where plastic pollution is becoming an increasingly significant issue.

Another advantage of polymer pelletizers is their flexibility in terms of design and operation. Manufacturers can choose from different types of pelletizers based on their specific needs and requirements. For example, some pelletizers may be designed for continuous operation, while others may be used for batch processing. Additionally, many modern pelletizers come with advanced features such as automation, sensors, and control systems, making them even more efficient and cost-effective.

In conclusion, polymer pelletizers are essential tools in the polymer processing industry, providing numerous benefits to manufacturers. From improving product quality to reducing waste and enhancing efficiency, these machines play a vital role in meeting the demands of modern society. As technology continues to advance, we can expect to see even more innovative and sophisticated polymer pelletizers on the market, further enhancing our ability to produce high-quality polymer products.