The Art of Rubber Tire Extrusion: An Insight into the Open-Roller Process

The open-roller process is a crucial step in the production of rubber tires, and it plays a significant role in the overall quality and performance of the tire. In this article, we will delve into the intricacies of the open-roller process, its significance in tire manufacturing, and how it contributes to the end product's durability and safety.

At the heart of the open-roller process lies the use of high-quality raw materials, such as natural or synthetic rubber compounds, which are mixed together to form a homogeneous mixture. This mixture is then fed into the open-roller extruder, where it undergoes a series of complex chemical reactions that transform the raw material into a finished tire.

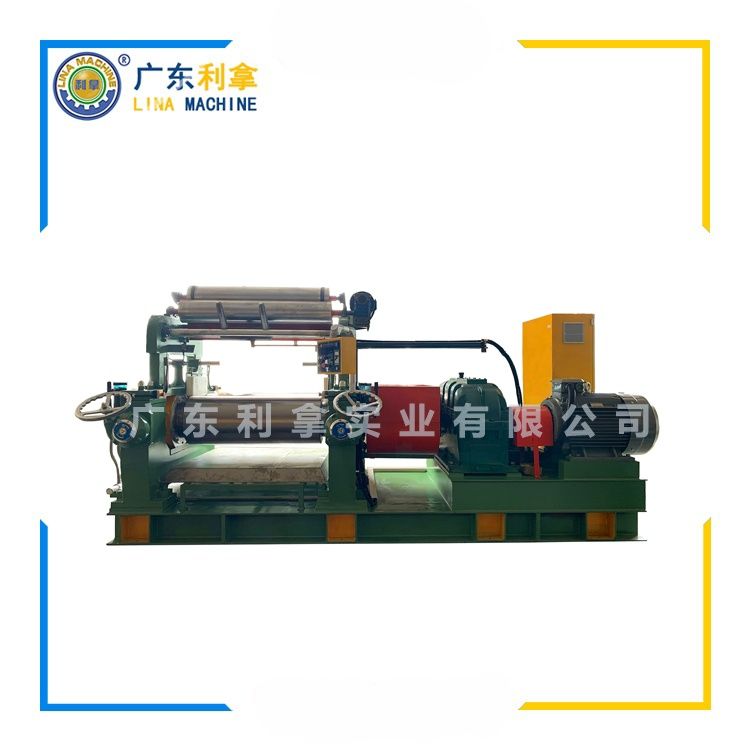

The open-roller process involves several key steps, including mixing, melting, extrusion, and shaping. During the mixing stage, the raw materials are thoroughly blended to ensure uniform distribution of ingredients. Once mixed, the mixture is heated to a temperature at which it becomes molten, allowing it to flow easily through the extruder.

The next step is extrusion, where the molten rubber is forced through a die, creating a continuous thread of rubber. This thread is then shaped into the desired shape of the tire, using specialized tools and techniques. The shaping process is critical in determining the final dimensions and characteristics of the tire, such as width, height, and tread pattern.

Once the tire is formed, it is cooled down to solidify the rubber and remove any excess heat. This cooling process is essential in preventing premature aging and ensuring the tire's structural integrity.

The open-roller process is not only crucial for producing high-quality tires but also has a significant impact on the environment. By reducing waste and minimizing energy consumption, the open-roller process helps to reduce greenhouse gas emissions and promote sustainable manufacturing practices.

In conclusion, the open-roller process is an integral part of the tire manufacturing process, from raw material preparation to final product formation. Its importance lies in its ability to produce high-quality tires with enhanced durability and safety features. As we continue to prioritize sustainability and environmental responsibility, the open-roller process continues to play a vital role in advancing our industry towards a more efficient and eco-friendly future.