The Role of Modified Plastic Granulators in the Manufacturing Industry

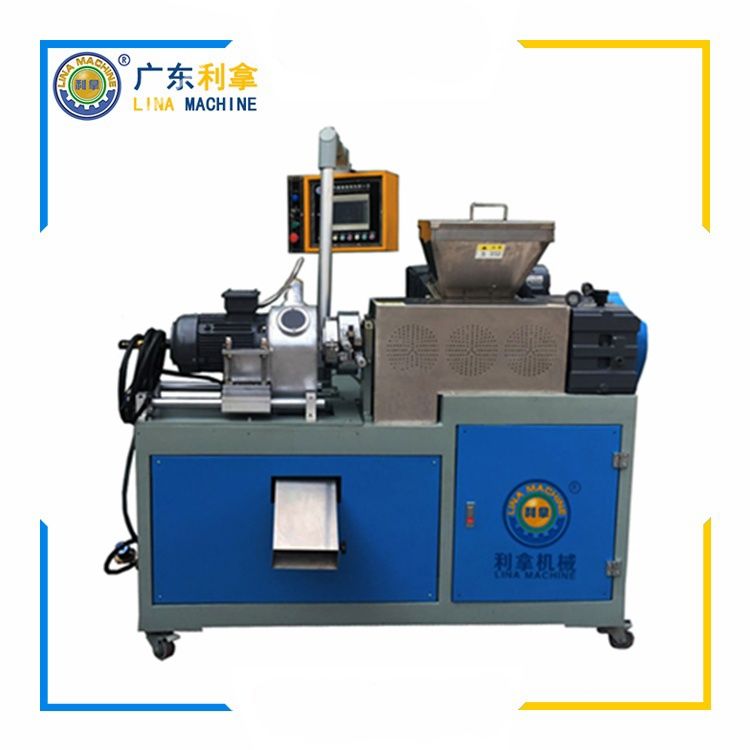

In the manufacturing industry, plastic materials are widely used for various applications such as packaging, construction, and electronics. However, traditional plastics may not meet all the specific requirements of different industries due to their inherent properties. To address this issue, modified plastic granulators have been developed to enhance the performance of plastic materials. These granulators can be classified into two main types: extrusion granulators and injection granulators.

Extrusion granulators are used for producing extruded products such as pipes, profiles, and sheet materials. These granulators can be equipped with various tools to process different types of plastics, including thermoplastics, thermosets, and elastomers. The key advantage of extrusion granulators is their ability to produce high-quality products with consistent dimensions and surface finishes. Additionally, they can also be used to add functional additives such as fillers, pigments, and reinforcements to improve the mechanical properties of the final product.

Injection granulators are designed for processing thermoplastics and thermosets into injection-molded parts. These granulators use a screw extruder to transfer molten plastic from the hopper to the mold cavity. The temperature and pressure control during the injection process are crucial for achieving the desired physical properties of the final product. In addition, injection granulators can also be equipped with cooling systems to prevent warping and shrinkage during the cooling phase.

The advantages of using modified plastic granulators include improved material efficiency, reduced waste, and enhanced product quality. By adjusting the parameters of the granulator, manufacturers can optimize the production process and achieve better cost savings. Additionally, these granulators can also help reduce energy consumption and minimize environmental impact by producing more sustainable products.

1. Modified Plastic Granulators

2. Extrusion Granulators

3. Injection Granulators

4. Material Efficiency

5. Product Quality

This article provides an overview of the role of modified plastic granulators in the manufacturing industry. We discuss the different types of granulators available and their respective advantages, such as improved material efficiency, reduced waste, and enhanced product quality. By understanding the importance of these granulators, manufacturers can optimize their production processes and achieve better cost savings while minimizing environmental impact.