The Role of Talc Powder Granulators in the Manufacturing Industry

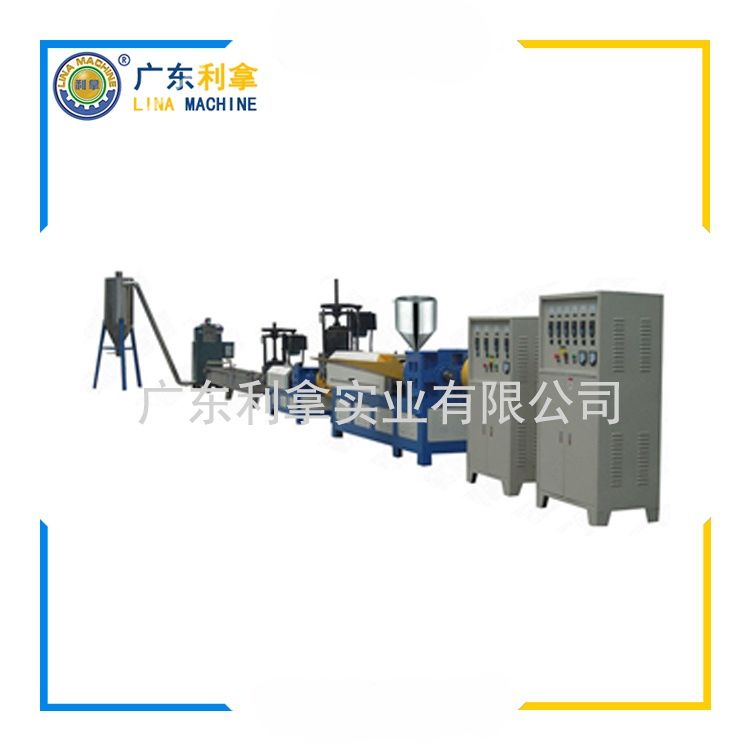

Talc powder granulators are essential tools in the manufacturing industry, particularly in the production of various types of products that require a fine and consistent texture. These machines are designed to process talc, a mineral commonly used as a filler or extender in plastics, rubber, paper, and other materials. By using these granulators, manufacturers can produce high-quality products with reduced waste and increased efficiency.

One of the primary functions of a talc powder granulator is to grind the raw material into a fine powder. This process involves passing the talc through a series of grinding rollers, which help break down the larger particles into smaller ones. The resulting powder is then collected and stored for future use.

Another important aspect of talc powder granulators is their ability to control the moisture content of the talc. Moisture is an essential ingredient in many products, but too much moisture can lead to poor quality and even safety hazards. By using granulators that have moisture control features, manufacturers can ensure that their products meet specific standards and regulations.

In addition to its technical functions, a talc powder granulator also plays a role in improving product consistency. By controlling the size and shape of the talc particles, manufacturers can create products with a uniform texture and appearance. This not only enhances the overall quality of the product but also reduces the need for additional processing steps later on.

Overall, talc powder granulators are crucial tools for any manufacturer looking to improve their product quality and efficiency. With their ability to grind talc into fine powder and control moisture levels, these machines are an essential component of the modern manufacturing process.