Understanding the Advantages of Graphite Bipolar Plate Pressing Machine Production Lines

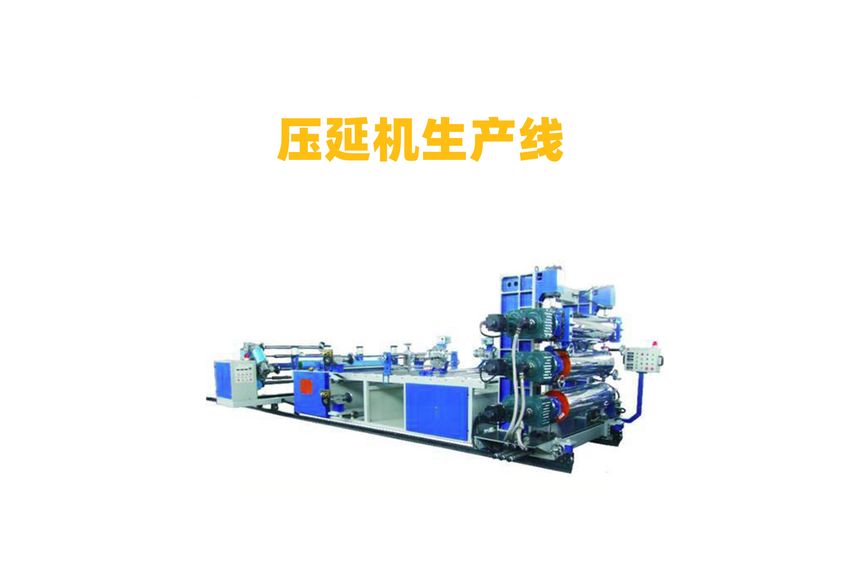

In the field of electroplating, the production line plays a crucial role in enhancing efficiency and quality. One such line is the graphite bipolar plate pressing machine, which has gained significant attention due to its superior performance in terms of cost-effectiveness, speed, and precision. This article aims to provide an in-depth analysis of the advantages of graphite bipolar plate pressing machines and their impact on the electroplating industry.

Firstly, let's discuss the concept of graphite bipolar plates. These are two parallel plates made of graphite material that are used in the electroplating process. The graphite plates serve as anode and cathode, allowing for the deposition of metal onto the surface of the workpiece. The pressing machine, on the other hand, is responsible for applying pressure to the graphite plates during the electroplating process.

Now, let's focus on the benefits of using graphite bipolar plate pressing machines. One of the most significant advantages is the increased speed and efficiency of the production line. With these machines, the electroplating process can be completed much faster than traditional methods, resulting in higher productivity. Additionally, the use of graphite bipolar plates ensures that the metal deposited onto the workpiece is uniform and consistent, which is essential for achieving high-quality products.

Another advantage of graphite bipolar plate pressing machines is their ability to reduce costs. Compared to traditional methods, these machines require less energy and generate lower electricity bills. This is because they operate at higher voltage levels, which results in more efficient use of power. Furthermore, the reduced need for manual labor means that there is a reduction in labor costs, making the production line more cost-effective overall.

Moreover, graphite bipolar plate pressing machines offer improved precision and accuracy in the electroplating process. The use of graphite plates ensures that the metal deposited onto the workpiece is even and precise, resulting in better quality products. Additionally, the press machine's ability to apply consistent pressure ensures that the metal layer remains intact throughout the process, preventing any defects or flaws from appearing on the final product.

Finally, graphite bipolar plate pressing machines have a positive impact on the environment. They consume less energy and generate fewer emissions compared to traditional methods, making them more sustainable and eco-friendly. Additionally, the use of graphite plates reduces the need for non-renewable materials, further contributing to environmental sustainability.

In conclusion, the graphite bipolar plate pressing machine is a game-changer in the electroplating industry. Its ability to increase speed, efficiency, reduce costs, improve precision, and contribute to environmental sustainability makes it an essential tool for any production line looking to enhance their operations. As the demand for high-quality, low-cost, and environmentally friendly products continues to rise, the use of graphite bipolar plate pressing machines will only become more prevalent in the future.