The Extruder Machine for Cable and Wires - A Comprehensive Guide

Cable and wire extrusion is a crucial process in the manufacturing industry, whereby plastic or metal materials are molded into continuous strands. This process is commonly used in the production of electrical wiring, cables, and other electrical components. In this article, we will explore the basic principles of the extruder machine for cable and wires, its working mechanism, and the various types of extruders available in the market.

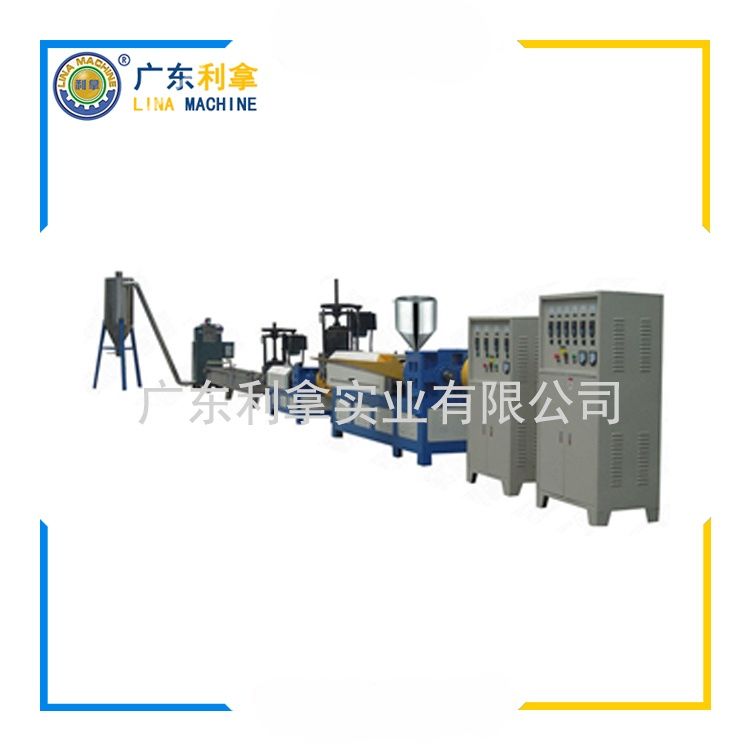

The Extruder Machine for Cable and Wires

The extruder machine is a complex piece of equipment that consists of several key components. These include the hopper, die plate, screw, barrel, and cooling system. The hopper is where the raw material is fed into the machine, while the die plate is responsible for shaping the material into the desired shape. The screw rotates inside the barrel to push the material through the die plate and onto the final product. The barrel is where the material is heated and cooled, which helps to ensure the quality of the final product. Finally, the cooling system helps to remove any residual heat from the material before it is ready to be collected.

Working Mechanism

The working mechanism of the extruder machine is based on the principle of mechanical compression. As the screw rotates, it compresses the material between two plates, which in turn forces the material through the die plate. The force applied by the screw is proportional to the speed of rotation, which determines the rate at which the material is pushed through the die plate. The pressure exerted by the screw also affects the size and shape of the final product.

Types of Extruders

There are several types of extruders available in the market, each with its own advantages and disadvantages. Here are some of the most common types:

1. Cone Extruder: This type of extruder is ideal for producing thin sheets and films. It has a high degree of flexibility and can handle a wide range of materials. However, it requires more energy to operate than other types of extruders.

2. Rod Extruder: This type of extruder is commonly used for producing wires and cables. It has a simple design and is easy to maintain. However, it may not be suitable for producing thicker materials.

3. Blown Film Extruder: This type of extruder is used for producing flexible films and sheeting. It has a low energy consumption and is suitable for producing large volumes of material.

4. Pellet Extruder: This type of extruder is ideal for producing small-sized products such as beads, pellets, and flakes. It has a compact design and is easy to transport. However, it may not be suitable for larger-scale production.

1. Extruder Machine

2. Cable and Wires

3. Working Mechanism

4. Types of Extruders

5. Cone Extruder

6. Rod Extruder

7. Blown Film Extruder

8. Pellet Extruder

9. Energy Consumption

10. Small-Scale Production

This article provides an in-depth exploration of the extruder machine for cable and wires, highlighting its working mechanism and different types of extruders available in the market. By understanding the principles behind the operation of these machines, manufacturers can optimize their production processes and improve the quality of their final products. Additionally, the article covers important factors such as energy consumption and small-scale production, which are essential considerations for those looking to reduce costs and increase efficiency.