The Four-Roll Silicon Rubber Extrusion Machine

The four-roll silicone rubber extruder is a crucial piece of machinery in the production process of silicone rubber products. It is widely used in the manufacturing industry, especially in the field of electronics and automotive industries. This machine is designed to extrude silicone rubber into various shapes and sizes, which are then processed further to meet specific requirements.

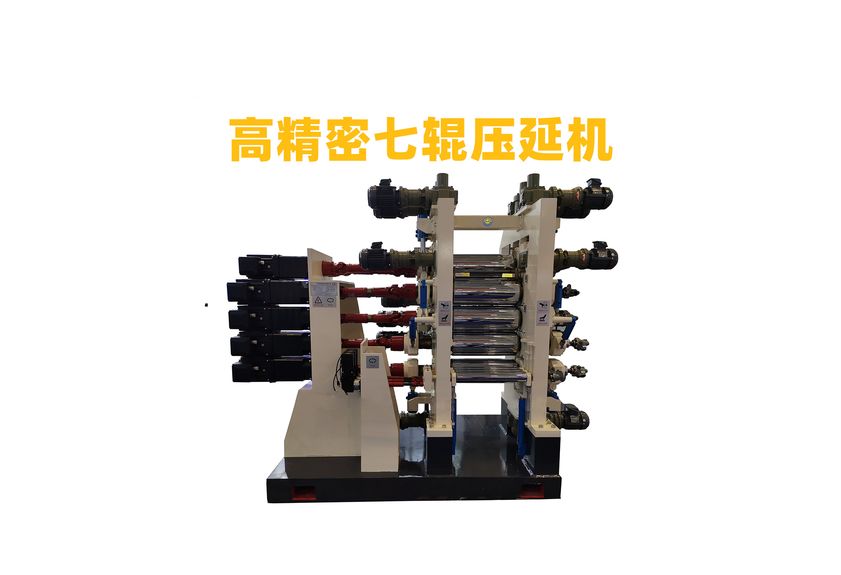

The four-roll silicone rubber extruder consists of four rollers that rotate around a central shaft. The rollers are made of high-quality stainless steel, which ensures their durability and smooth operation. The rollers are arranged in a way that allows for easy adjustment of the width and thickness of the extruded silicone rubber.

The extruder has a powerful motor that drives the rollers at high speeds, resulting in a high-pressure flow of silicone rubber. This pressure helps to ensure that the silicone rubber is evenly distributed throughout the entire length of the extruded product.

In addition to its mechanical features, the four-roll silicone rubber extruder also has some advanced technological features. For example, it can be equipped with different types of die plates to produce different shapes and sizes of silicone rubber products. Moreover, it can also be connected to other machines such as injection molding machines or compression molding machines, allowing for a more efficient production process.

Overall, the four-roll silicone rubber extruder is an essential tool for the production of silicone rubber products. Its high efficiency, precision, and versatility make it a popular choice among manufacturers.