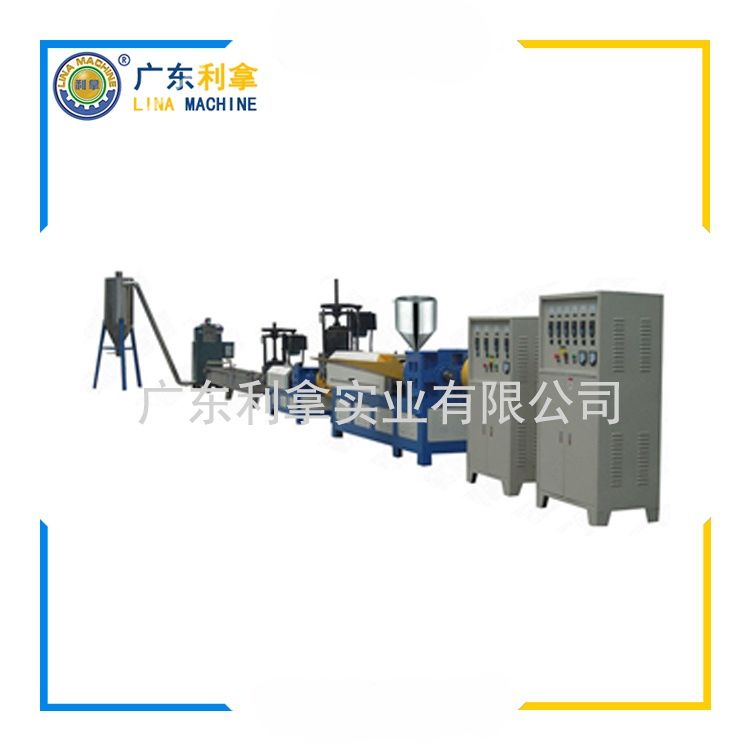

The Mini Double Cone Granulator: A Comprehensive Guide to Its Operation and Application

The mini double cone granulator is a versatile tool that has found its place in the industrial world. This compact machine is designed to produce granular materials with high efficiency and consistency. In this article, we will explore the basic principles of operation, key features, and applications of this innovative equipment.

At its core, the mini double cone granulator works by using two concentric cylinders to crush and granulate raw materials. As the material enters the first cylinder, it is subjected to compression and extrusion, resulting in a uniformly shaped granular product. The second cylinder then acts as a die, shaping the granular material into the desired size and shape.

One of the most significant advantages of the mini double cone granulator is its ability to handle a wide range of materials. From agricultural waste to construction aggregates, this machine can produce granular products from virtually any type of raw material. Additionally, the granulation process is highly efficient, allowing for reduced energy consumption and lower operating costs.

In terms of design, the mini double cone granulator is compact and easy to maneuver. It is equipped with advanced technology, including sensors and control systems that allow for precise adjustments in temperature, pressure, and speed. This ensures that the granulation process is consistent and reliable, producing high-quality granular products every time.

Applications of the mini double cone granulator are diverse and varied. Some common uses include:

1. Agricultural waste management: This machine can be used to convert agricultural waste such as corn stalks, wheat straw, and other crop residues into granulated fertilizers or soil amendments.

2. Construction aggregate production: The granulation process can be used to produce aggregates for use in construction projects, reducing the need for bulky materials and increasing efficiency.

3. Recycling industry: The granulation process can be applied to various types of recycling materials, such as plastic bottles, glass, and metal scraps, to produce new products or reduce waste.

4. Energy sector: The granulation process can be used to produce granular fuel pellets, which can be used as an alternative to traditional coal or oil.

In conclusion, the mini double cone granulator is a powerful tool that offers numerous benefits for industries across multiple sectors. Its ability to handle a wide range of materials, efficient operation, and advanced technology make it an essential piece of equipment for anyone looking to improve their granulation process. So why not consider investing in a mini double cone granulator today?