The Role of Two Roll Mills in Rubber Technology

The two roll mill is a critical piece of equipment used in the rubber industry for mixing and processing various types of rubber compounds. This machine has been around for centuries, and its design has evolved over time to meet the needs of modern-day rubber manufacturing. In this article, we will explore the basic principles of operation, the different types of two roll mills available, their applications in the rubber industry, and some tips for maintaining optimal performance.

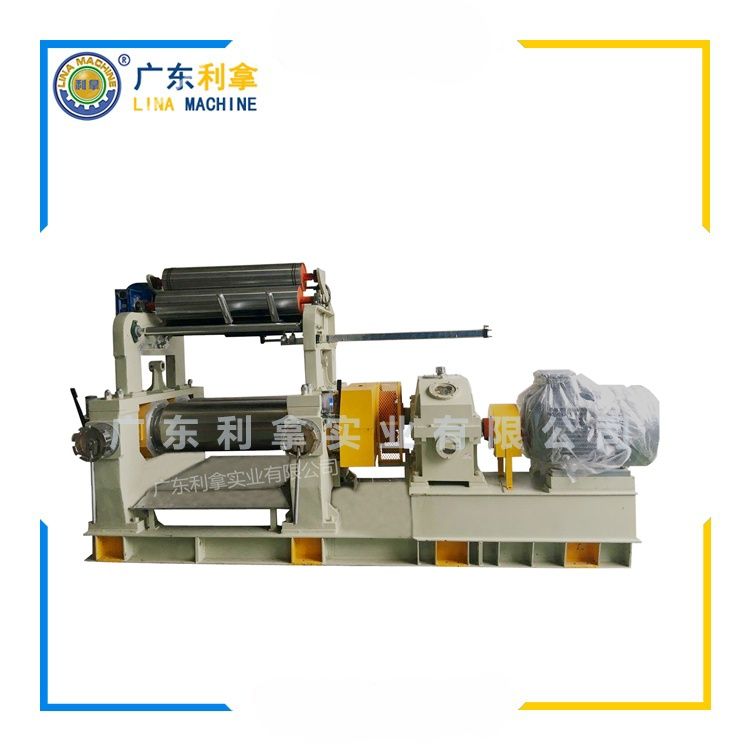

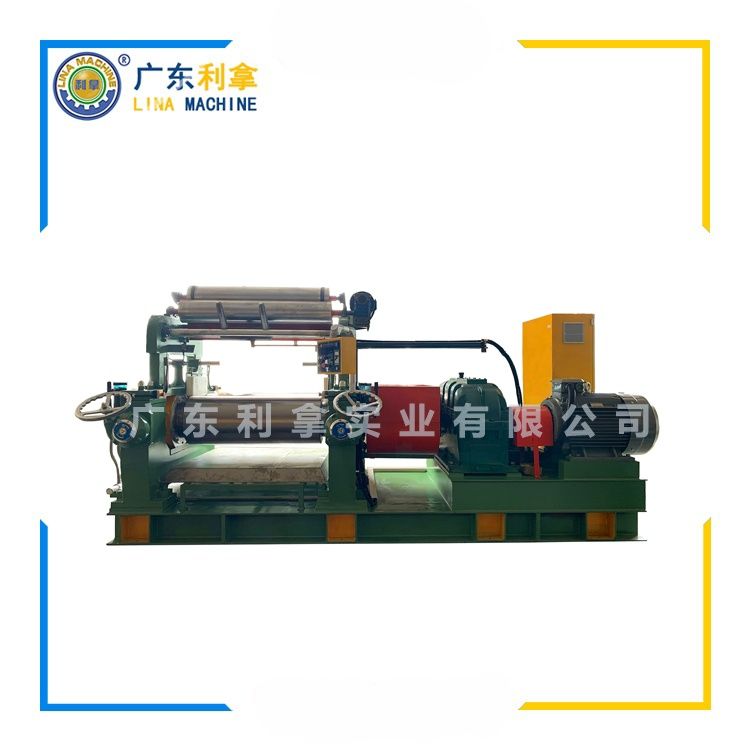

The two roll mill consists of two parallel metal rollers that rotate against each other to mix and knead the rubber compound. The rollers are usually made of steel or stainless steel, and they are mounted on a shaft that rotates at high speeds. As the rollers move past each other, they transfer heat and pressure to the rubber compound, which helps to melt it and create a uniform texture.

There are several types of two roll mills available, each with its own unique features and capabilities. The most common types include the flat-roll mill, the drum-roll mill, and the rotary-roll mill. Each type has its own advantages and disadvantages, so it's important to choose the right mill for your specific needs.

One of the main applications of two roll mills in the rubber industry is in the production of natural rubber latex. Natural rubber latex is a valuable raw material that can be processed into various products such as tires, hoses, and gloves. The two roll mill is essential in this process because it allows for the efficient mixing and kneading of the latex, which is necessary to achieve the desired texture and consistency.

Another application of two roll mills is in the production of synthetic rubber compounds. Synthetic rubber compounds are used in a variety of industrial applications, including automotive parts, electronics, and construction materials. The two roll mill is crucial in this process because it ensures that the rubber compounds are mixed and processed properly, resulting in high-quality products.

To maintain optimal performance, it's important to regularly clean and maintain the two roll mill. This includes checking the rollers for any wear or damage, lubricating them periodically, and replacing them when necessary. Additionally, regular maintenance can help to prevent downtime due to mechanical failures, which can result in significant losses for the rubber industry.

In conclusion, the two roll mill is an essential piece of equipment in the rubber industry for mixing and processing various types of rubber compounds. Its ability to create a uniform texture and high-quality products makes it a vital tool for manufacturers looking to produce high-performance products. By understanding the basic principles of operation, the different types of two roll mills available, and how to maintain them, you can ensure that your rubber production runs smoothly and efficiently.