The Development and Application of Absorbent Material Rolling Machines

In the field of materials science, absorbent material rolling machines have become an essential tool for manufacturing various absorbent products. These machines are designed to process a wide range of absorbent materials, including polymers, minerals, and composites, into uniform sheets or strips that meet specific performance requirements.

The development of absorbent material rolling machines has been driven by the increasing demand for absorbent materials in various industries, such as healthcare, agriculture, and construction. As technology advances, these machines have become more efficient, cost-effective, and environmentally friendly, making them a valuable asset for manufacturers.

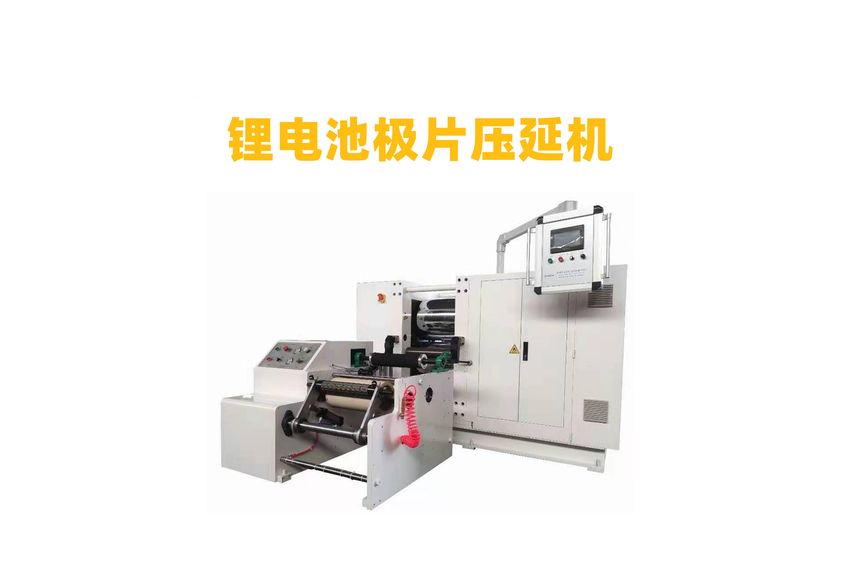

One of the key features of absorbent material rolling machines is their ability to process a wide range of materials at high speeds and low energy consumption. This is achieved through the use of advanced control systems and sensors that enable precise measurement and adjustment of parameters during the processing cycle.

Another important aspect of these machines is their ability to produce high-quality absorbent products with consistent dimensions and properties. This is achieved through the use of specialized rollers and pressure settings that ensure uniform thickness and strength throughout the sheet.

In addition to their technical capabilities, absorbent material rolling machines also play a crucial role in reducing waste and minimizing environmental impact. By using renewable energy sources and implementing recycling programs, manufacturers can reduce their carbon footprint and contribute to sustainable development goals.

Overall, the development and application of absorbent material rolling machines have had a significant impact on the industry, enabling manufacturers to produce high-quality absorbent products while minimizing costs and environmental impact. As technology continues to evolve, it is likely that these machines will continue to play an important role in shaping the future of the absorbent materials industry.