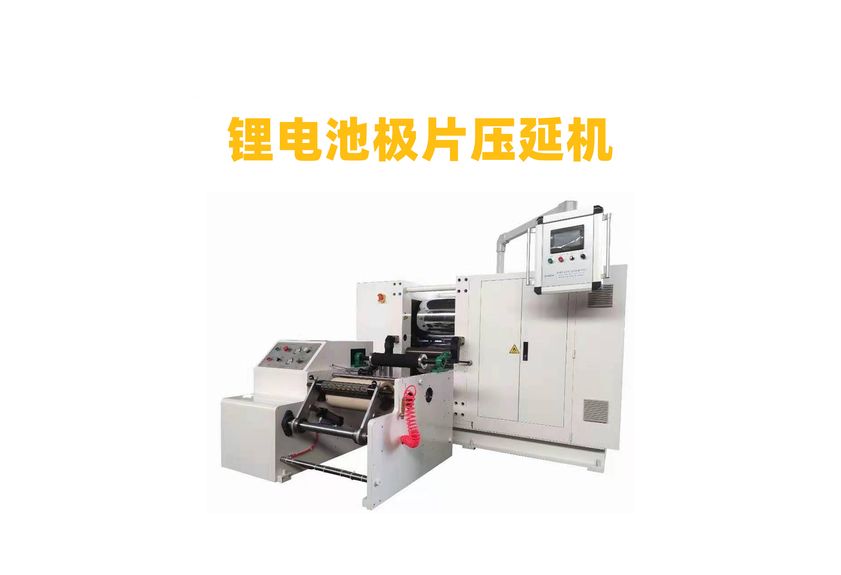

Advanced PCM Thermal Conductive Phase Change Materials Precision Rolling Machine

The development of precision rolling machines for the production of advanced PCM (Phase Change Materials) thermal conductive phase change materials has been a key focus in the field of thermal management. These machines are designed to precisely roll and shape high-quality PCM sheets, ensuring consistency in thickness, uniformity, and precise dimensions. The use of these machines is essential in the manufacturing process of thermally efficient building components, such as solar panels, heat exchangers, and thermal storage systems.

One of the main advantages of using precision rolling machines for PCM materials is their ability to produce consistent and high-quality sheets. This is achieved through the use of advanced control systems that allow for precise adjustments in roller pressure, speed, and temperature, which can be tailored to meet the specific requirements of each material. This results in a more reliable and efficient production process, reducing waste and minimizing defects.

Another important aspect of precision rolling machines for PCM materials is their ability to handle complex shapes and sizes. With the help of advanced software and algorithms, these machines can create intricate designs that are difficult or impossible to achieve with traditional manual methods. This not only enhances the aesthetic appeal of the final product but also improves its performance by maximizing contact area between the PCM and the surrounding environment.

In addition to their technical advantages, precision rolling machines for PCM materials also offer significant cost savings. By reducing the need for manual labor and increasing efficiency, these machines can significantly reduce production costs. Moreover, they can be used to produce large quantities of PCM sheets, making them ideal for industrial applications where cost is a critical factor.

Finally, precision rolling machines for PCM materials have a positive impact on the environment. By reducing waste and improving efficiency, these machines contribute to a more sustainable future by reducing the carbon footprint associated with traditional manufacturing processes. They also promote innovation and technological advancements in the field of thermal management, leading to new and innovative solutions that address global challenges such as climate change and energy conservation.

1. Precision Rolling Machines

2. Advanced PCM Thermal Conductive Phase Change Materials

3. Manufacturing Process

4. Consistency in Quality

5. Cost Savings

6. Environmental Impact

7. Technological Advancements

This article provides an in-depth analysis of the precision rolling machines used in the manufacturing process of advanced PCM thermal conductive phase change materials. The focus is on the importance of these machines in achieving consistent quality, reducing costs, and promoting environmental sustainability. The article highlights the benefits of using these machines in industries ranging from solar panels to heat exchangers, highlighting their potential to revolutionize the way we manage our energy needs.