The Art of Rubber Making: An Overview of Rubber Processing Machines

Rubber processing machines play a crucial role in the production of rubber products. These machines are designed to transform raw materials into high-quality rubber compounds that can be molded, extruded, or vulcanized into various forms such as tires, hoses, and gloves. In this article, we will explore the different types of rubber processing machines and their applications in the rubber industry.

1. Extruders: Extruders are the heart of the rubber processing industry. They are used to convert latex or other rubber compounds into sheets, tubes, or profiles. Extruders come in various sizes and configurations, depending on the desired product shape and size. Some common types of extruders include rotary screw extruders, twin-screw extruders, and profile extruders.

2. Valves: Valves are essential components of rubber processing machines that control the flow rate of the rubber compound. They are used to regulate the amount of material being fed into the extruder and to prevent backflow during extrusion. There are two main types of valves: gate valves and butterfly valves.

3. Heaters: Heaters are used to melt the rubber compound before it is processed by the extruder. They are typically located downstream of the extruder and are responsible for maintaining the temperature of the rubber compound at a specific level. Heaters can be manual or automatic, depending on the application and budget.

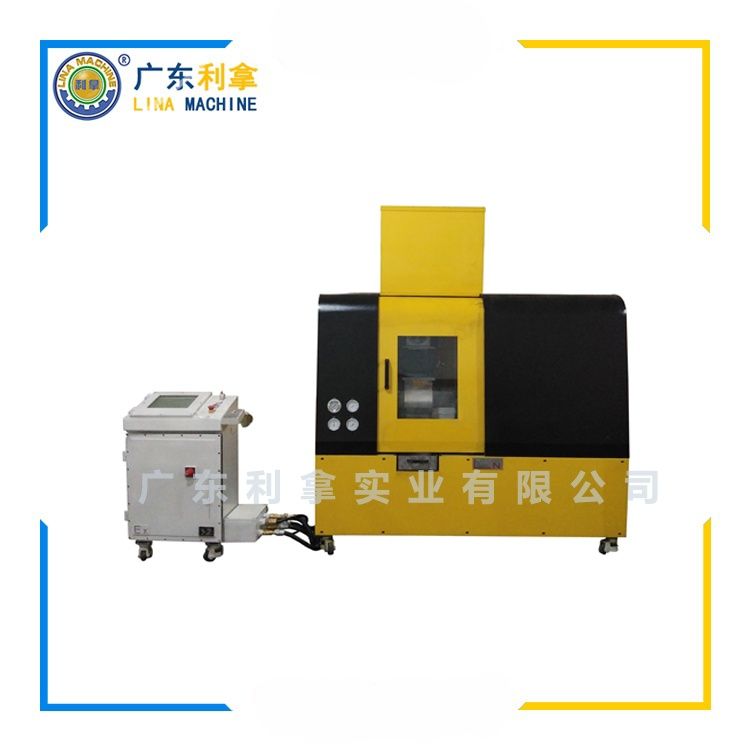

4. Vulcanizers: Vulcanization is the process of cross-linking rubber compounds to increase their strength and durability. Vulcanizers are used to achieve this effect by applying heat and pressure to the rubber compound. There are two main types of vulcanizers: hot vulcanizers and cold vulcanizers. Hot vulcanizers use steam or hot oil to heat the rubber compound, while cold vulcanizers use a chemical reaction to cross-link the rubber.

5. Cutters: Cutters are used to remove excess material from the end of the rubber product after vulcanization. They are typically located upstream of the vulcanizer and are responsible for shaping the final product into its desired form. Cutter types include knife cutters, die cutters, and wire cutters.

- Rubber Processing Machines

- Extruders

- Valves

- Heaters

- Vulcanizers

- Cutters

This article provides an in-depth overview of the various types of rubber processing machines used in the rubber industry. From extruders to cutters, each machine plays a critical role in transforming raw materials into high-quality rubber products. By understanding the functions and applications of these machines, manufacturers can optimize their production processes and improve the quality of their products.