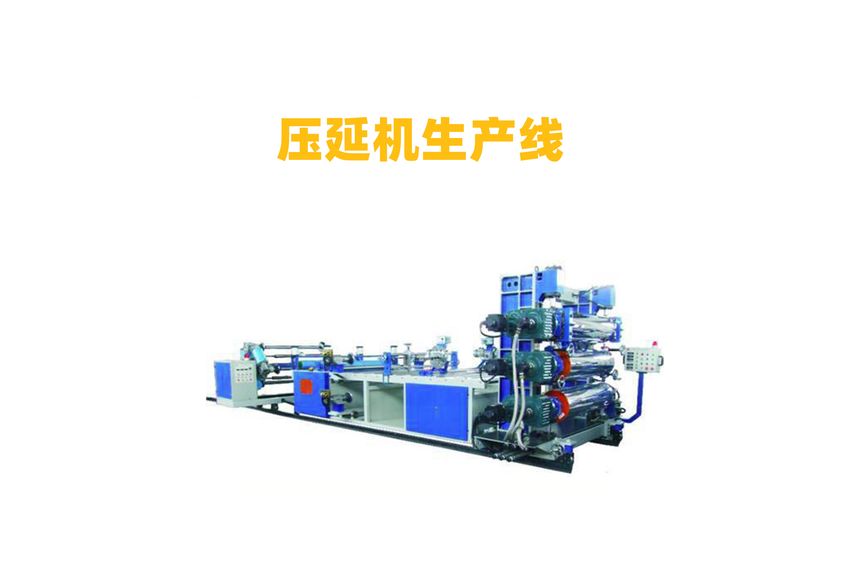

The Seven-Roll Extrusion Machine

The seven-roll extrusion machine is a critical tool in the manufacturing industry, particularly in the production of sheet metal products. This versatile piece of machinery is capable of shaping and molding various materials into desired shapes with precision and efficiency.

At its core, the seven-roll extruder consists of seven parallel rollers that work together to pressurize and shape the material being fed into the machine. Each roller has a unique function, from the primary roll that feeds the material into the machine to the last roll that removes the formed product. The rollers are arranged in a specific order, with each one exerting pressure on the material as it passes through them, resulting in a uniform and consistent product.

One of the key features of the seven-roll extruder is its ability to handle a wide range of materials, including steel, aluminum, and plastics. This flexibility makes it ideal for a variety of applications, from automotive parts to electronic components. The machine's precision control system ensures that the final product meets industry standards, making it an essential tool for any manufacturer looking to produce high-quality products quickly and efficiently.

In addition to its technical capabilities, the seven-roll extruder also offers significant advantages in terms of cost-effectiveness. By using fewer machines than traditional methods, manufacturers can reduce their overall investment in equipment. Additionally, the machine's ability to process multiple materials simultaneously means that it can be used to produce a variety of products quickly, further increasing efficiency.

Despite its many benefits, the seven-roll extruder does require some maintenance and upkeep to ensure optimal performance. Regular cleaning and lubrication of the rollers are essential to prevent wear and tear, which can affect the quality of the final product. However, with proper care and attention, this powerful tool can continue to deliver high-quality results for years to come.

1. Seven-roll extrusion machine

2. Manufacturing industry

3. Material processing

4. Precision control system

5. Cost-effectiveness

The seven-roll extrusion machine is a crucial tool in the manufacturing industry, offering unparalleled precision and efficiency in material processing. With its ability to handle a wide range of materials, including steel, aluminum, and plastics, this versatile piece of machinery is ideal for a variety of applications, from automotive parts to electronic components. Its advanced precision control system ensures that the final product meets industry standards, making it an essential tool for any manufacturer looking to produce high-quality products quickly and efficiently. Despite its complex nature, the seven-roll extruder requires regular maintenance and upkeep to ensure optimal performance. With proper care and attention, this powerful tool can continue to deliver high-quality results for years to come.