Advanced Technology Meets Innovation: The Development of a High-Performance Graphene Thermal Conductive Pad Pressing Machine

In the realm of advanced manufacturing, the integration of cutting-edge materials and technologies is key to achieving superior performance. One such area where this principle is particularly evident is in the production of high-quality graphene thermal conductive pads. These pads play a crucial role in enhancing the efficiency of heat dissipation in electronic devices, from smartphones to power supplies, ensuring that they operate at optimal temperatures for extended periods.

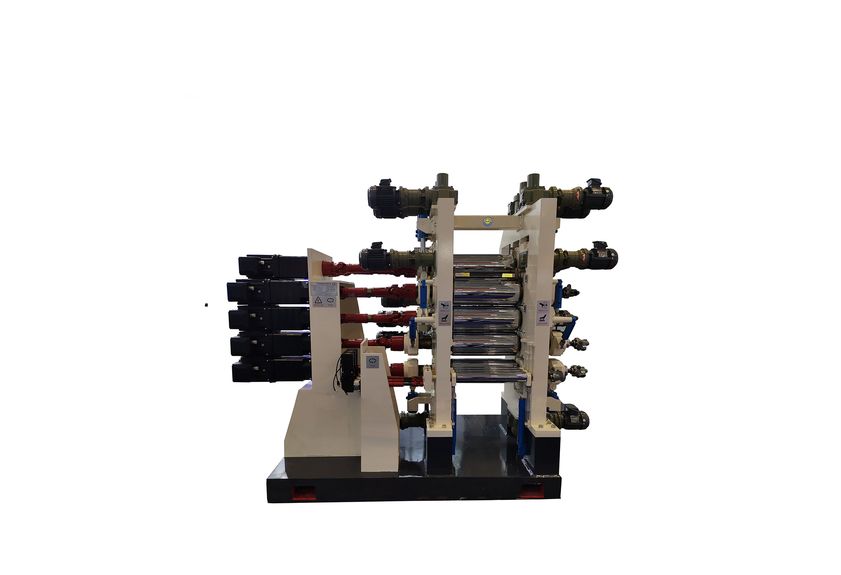

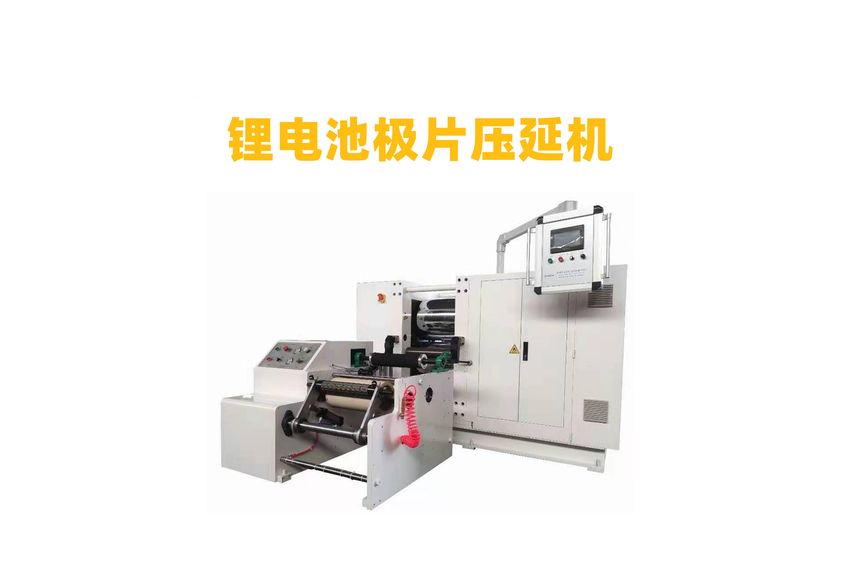

The development of a graphene thermal conductive pad pressing machine is a testament to the synergy between science and engineering. This innovative piece of machinery uses advanced techniques to precisely mold graphene sheets into precise shapes, thereby creating thermally efficient pads that can withstand the rigorous conditions of high-performance electronics.

One of the key features of this machine is its ability to control the thickness and density of the graphene layers, allowing for customized designs that meet the specific needs of each application. This precision not only enhances the overall performance of the pad but also minimizes waste and maximizes efficiency.

Another significant advantage of this machine is its ability to process large volumes of graphene material quickly and efficiently. With minimal downtime and minimal energy consumption, it is an ideal solution for high-volume production lines, enabling manufacturers to maintain consistent quality levels while reducing costs.

In conclusion, the development of a graphene thermal conductive pad pressing machine represents a significant advancement in the field of electronics manufacturing. By leveraging the latest technologies and materials, this machine has enabled manufacturers to create highly efficient and cost-effective thermal pads that are essential for the continued growth of the industry. As we continue to push the boundaries of what is possible in manufacturing, it is clear that innovation will remain at the heart of our success.