PCM相变化导热硅胶压延机:创新技术在材料加工中的应用

The development of PCM (Phase Change Material) thermal management systems has been a significant advancement in the field of electronics and energy storage. This innovative technology is revolutionizing the way we manage heat in electronic devices, offering unparalleled performance and efficiency. In this article, we will explore the application of PCM thermal management systems in the production process of PCM phase change thermal gel pads through the use of PCM phase change thermal gel pad press machines.

PCM phase change thermal gel pads are essential components in various electronic devices, including smartphones, laptops, and gaming consoles. These pads work by absorbing and dissipating heat generated by the device, ensuring that the device remains cool and comfortable to use. The production process for PCM phase change thermal gel pads involves several steps, including mixing, molding, and curing. To achieve these processes efficiently and accurately, PCM phase change thermal gel pad press machines have been developed.

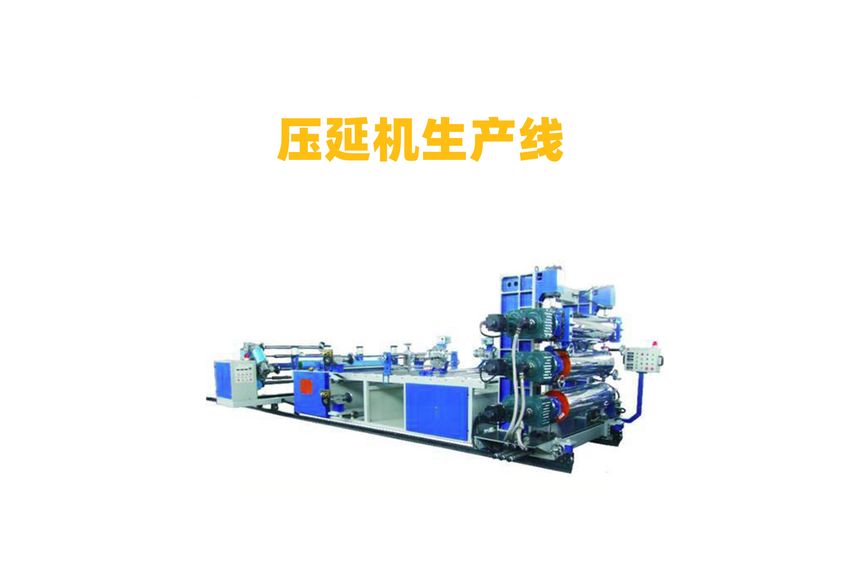

PCM phase change thermal gel pad press machines are designed to handle high-volume production of PCM phase change thermal gel pads. These machines use advanced automation and control systems to ensure consistent quality and accuracy in the production process. They incorporate state-of-the-art technologies such as computer-controlled rollers, precise temperature control, and automated feeding mechanisms. These features enable the machines to produce PCM phase change thermal gel pads with high precision and consistency, meeting the demands of modern electronic devices.

One of the key advantages of PCM phase change thermal gel pad press machines is their ability to improve productivity and reduce labor costs. By using these machines, manufacturers can increase production capacity and reduce downtime caused by manual labor. Additionally, they can minimize errors and variability in product quality, which can be a significant issue in traditional production methods.

Another benefit of PCM phase change thermal gel pad press machines is their ability to enhance product quality. These machines use advanced sensors and monitoring systems to detect any deviations from the desired specifications during the production process. This ensures that each batch of PCM phase change thermal gel pads meets the highest standards of quality and performance.

In conclusion, PCM phase change thermal gel pad press machines play a crucial role in the production process of PCM phase change thermal gel pads. These machines offer numerous benefits, including increased productivity, reduced labor costs, improved product quality, and enhanced automation capabilities. As the demand for high-quality PCM phase change thermal gel pads continues to grow, the adoption of PCM phase change thermal gel pad press machines is expected to expand further.