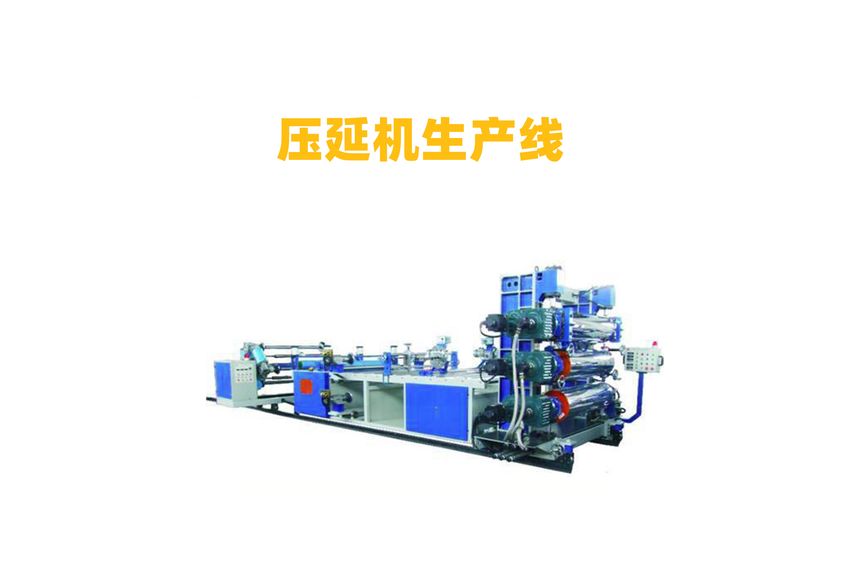

The Four-Roll Rolling Press: A Detailed Guide to Its Function and Applications

The four-roll rolling press is a versatile tool used in the manufacturing industry for shaping metal sheets into various shapes and sizes. This machine is designed to efficiently reduce the thickness of sheet metal, which is essential for many industrial applications such as automotive, aerospace, and construction industries.

The basic working principle of a four-roll rolling press involves passing the sheet metal through two sets of rollers that are arranged in a V-shaped configuration. These rollers exert pressure on the sheet metal, causing it to be deformed and thinned out. As the sheet metal moves through the rollers, it is subjected to a series of compression and stretching forces, resulting in its uniform thinning.

One of the key advantages of the four-roll rolling press is its ability to produce high-quality products with minimal waste. By controlling the speed and pressure applied to the sheet metal, manufacturers can achieve consistent results without sacrificing material integrity or quality. Additionally, this machine is highly efficient, allowing for faster production times and reduced energy consumption compared to other methods of sheet metal processing.

In addition to its practical applications, the four-roll rolling press has also become increasingly popular in research and development settings. Many companies invest in these machines to explore new materials and processes, as well as to develop innovative designs that improve efficiency and reduce costs.