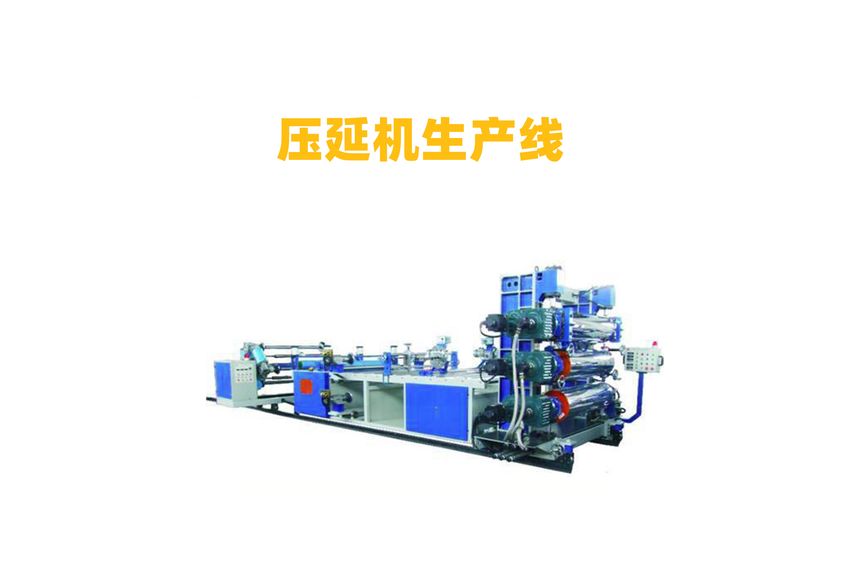

The Liquid Thermal Conductive Silicone Rolling Machine

The liquid thermal conductive silicone rolling machine is a crucial tool in the manufacturing industry, particularly in the electronics and aerospace sectors. This machine is designed to produce high-quality, precise, and uniform sheets of thermally conductive silicone rubber. It is essential for ensuring that components are cooled effectively during operation, reducing heat dissipation and enhancing performance.

The liquid thermal conductive silicone rolling machine utilizes advanced technology to achieve its impressive results. It features a roller system that can be adjusted to different thicknesses, allowing for precise control over the final product's dimensions. The machine also incorporates a heating element that ensures even heating of the silicone rubber, preventing hot spots or cold spots from forming during the process.

One of the key benefits of using this machine is its ability to produce high-quality sheets with minimal defects. The machine's automated controls ensure that each sheet produced is consistent in thickness, width, and length, which helps to reduce waste and improve efficiency. Additionally, the machine's precision rollers allow for accurate cutting and trimming of the sheets, further enhancing their quality.

In addition to its technical advantages, the liquid thermal conductive silicone rolling machine also has a significant impact on the environment. By producing sheets of silicone rubber that are more efficient at dissipating heat, it reduces the need for additional cooling systems, leading to lower energy consumption and reduced greenhouse gas emissions.

Overall, the liquid thermal conductive silicone rolling machine is an essential tool for any manufacturer looking to produce high-quality, thermally conductive silicone rubber sheets. Its advanced technology and environmental benefits make it a valuable investment in the future of manufacturing.