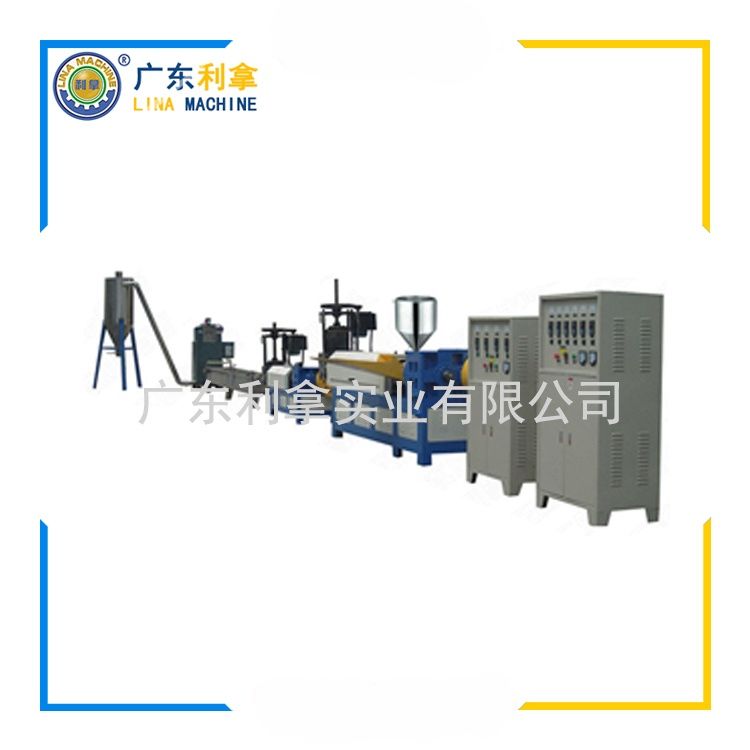

The Extrusion and Pelletizing Machine for Cables and Wires

The extrusion and pelletizing machine is a crucial tool in the production of electrical wires and cables. This machine is designed to process raw materials into high-quality products that meet the standards of various industries. The process involves melting the raw material, shaping it into a desired shape, and then cooling it down to solidify it into a pellet. The resulting pellet can be used as a building block for new products or simply as raw material for further processing.

One of the key features of this machine is its ability to handle a wide range of materials. It can work with different types of metals, plastics, and even composite materials. This makes it versatile and suitable for a variety of applications. Additionally, the machine's precision control system ensures that the final product meets the required specifications, such as diameter, length, and weight.

Another advantage of this machine is its efficiency. By using advanced technology, it can produce high-quality products quickly and efficiently. This not only saves time but also reduces waste and costs associated with manual labor. Furthermore, the machine's automation feature allows for precise control over the entire process, from feeding to cooling to pellet formation.

In conclusion, the extrusion and pelletizing machine is an essential tool for the production of electrical wires and cables. Its versatility, precision, and efficiency make it a preferred choice for many industries. As technology continues to advance, we can expect to see even more innovative designs and features that will enhance the quality and productivity of this machine.