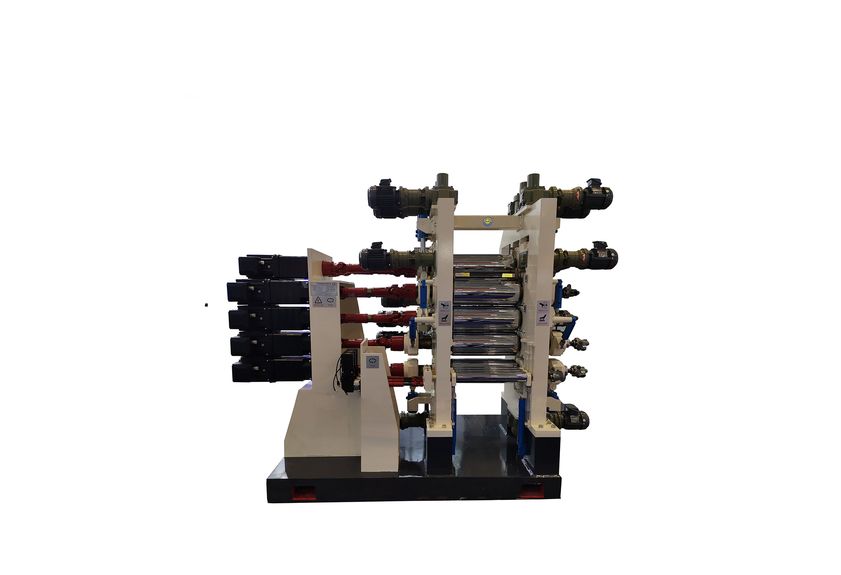

The PET Vacuum Pressing Machine: An Innovative Tool for Manufacturing Polyethylene Terephthalate Films

The PET vacuum pressing machine is a crucial tool in the production of polyethylene terephthalate (PET) films. This versatile machine has revolutionized the industry by offering efficient and cost-effective solutions for the manufacture of various types of PET products.

One of the main advantages of using a PET vacuum pressing machine is its ability to produce high-quality films with consistent thickness and uniformity. This ensures that the final product meets the required specifications and meets the needs of various industries, such as packaging, beverage containers, and medical devices.

Another significant benefit of this machine is its flexibility in terms of material handling. It can be used to process a wide range of plastic materials, including polypropylene, polystyrene, and other thermoplastics. This makes it an ideal choice for businesses that need to switch between different materials or expand their product line.

In addition to its manufacturing capabilities, the PET vacuum pressing machine also offers several safety features. These include automatic shut-off systems, emergency stop buttons, and protective gear for operators. These measures help ensure that the machine is operated safely and efficiently, while minimizing the risk of accidents or injuries.

Overall, the PET vacuum pressing machine is an essential tool for anyone looking to produce high-quality PET films at a competitive price. Its advanced technology and user-friendly design make it an ideal choice for businesses of all sizes, from small startups to large corporations.