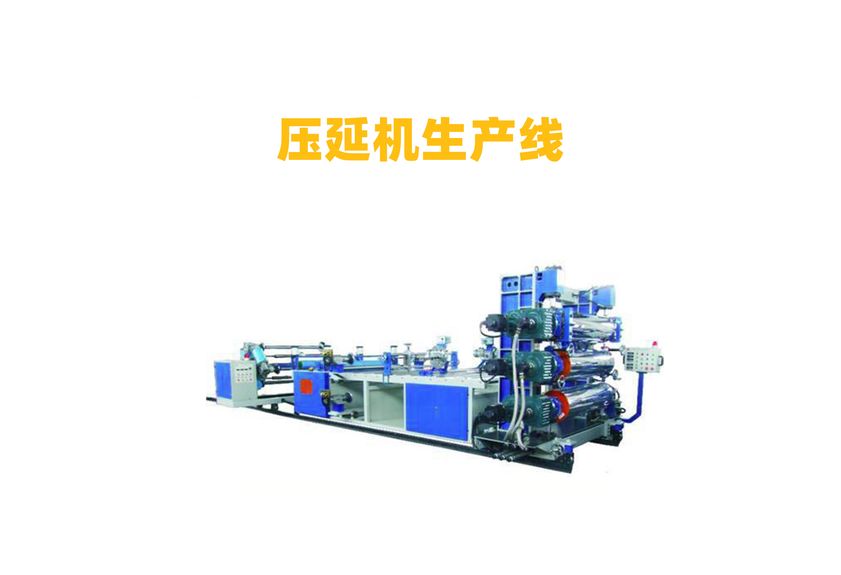

The Liquid Thermal Conductive Silicone Rolling Press

The liquid thermal conductive silicone rolling press is a crucial tool in the manufacturing industry, particularly in the electronics and aerospace sectors. This machine is designed to roll sheets of thermally conductive silicone rubber onto various substrates, such as circuit boards or heat sinks, to create an effective thermal interface material (TIM). The liquid thermal conductive silicone is a unique material that combines the flexibility of silicone with the thermal conductivity of metals, making it ideal for applications where flexibility and thermal efficiency are required.

The liquid thermal conductive silicone rolling press consists of several key components. First, there is the roller assembly, which is responsible for applying pressure and evenly distributing the silicone rubber across the substrate. The rollers are made from high-quality materials such as stainless steel or ceramic, ensuring longevity and minimal wear over time. Next, there is the heating system, which provides the necessary temperature to activate the liquid silicone and facilitate its flow. The heating system is typically controlled by a computer program, allowing for precise temperature control and adjustment during the process.

In addition to the roller assembly and heating system, the liquid thermal conductive silicone rolling press also includes a cooling system to maintain the proper working temperature of the silicone rubber. This system helps to prevent overheating and ensures that the silicone remains fluid throughout the process. Finally, there is the control panel, which allows operators to monitor and adjust the process parameters, including pressure, temperature, and speed.

The benefits of using a liquid thermal conductive silicone rolling press are numerous. One of the main advantages is its ability to produce high-quality TIMs with minimal waste. By using this machine, manufacturers can achieve consistent results and reduce costs associated with manual labor and subpar product quality. Additionally, the liquid silicone allows for easy integration into existing manufacturing processes, making it a cost-effective solution for many companies.

Another advantage of the liquid thermal conductive silicone rolling press is its flexibility. It can be used to manufacture a wide range of products, including electronic devices, aerospace components, and automotive parts. This makes it a valuable tool for businesses looking to expand their product lines and increase production capacity.

Finally, the liquid thermal conductive silicone rolling press is environmentally friendly. Unlike traditional methods of manufacturing TIMs, which often involve toxic chemicals and energy-intensive processes, this machine uses non-toxic materials and minimizes waste. This not only reduces environmental impact but also contributes to sustainable manufacturing practices.

1. liquid thermal conductive silicone rolling press

2. thermal interface material (TIM)

3. silicone rubber

4. manufacturing process

5. environmentally friendly

The liquid thermal conductive silicone rolling press is a highly efficient and versatile tool for manufacturing thermal interface materials (TIMs). With its advanced technology and state-of-the-art features, this machine enables manufacturers to produce high-quality TIMs quickly and efficiently, while reducing costs and minimizing waste. Its use is particularly beneficial for businesses looking to expand their product lines and increase production capacity, making it an essential investment for those seeking sustainable manufacturing practices.