Advanced Thermal Management with Graphene-Based Thermal Conductive Pad Pressing Machines

In the realm of electronics and thermal management, advancements in technology have led to the development of innovative solutions that enhance efficiency and reliability. One such solution is the use of graphene-based thermal conductive pads, which are being increasingly adopted in various industries for their exceptional thermal conductivity properties. These pads are designed to provide superior heat dissipation capabilities, making them an essential component in high-performance electronic devices, automotive components, and other thermally demanding applications.

The graphene-based thermal conductive pads are made from a thin layer of graphene material, which has unique mechanical and thermal properties that make it highly effective at transferring heat. This material is known for its exceptional electrical conductivity, which allows for rapid heat dissipation even when subjected to high temperatures. Additionally, graphene's high surface area to volume ratio facilitates better contact between the pad and the substrate, enhancing heat transfer efficiency.

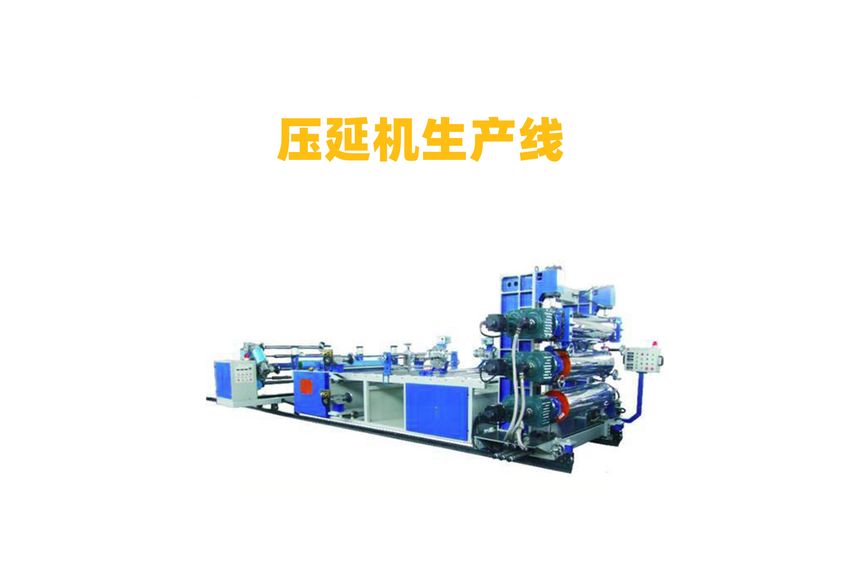

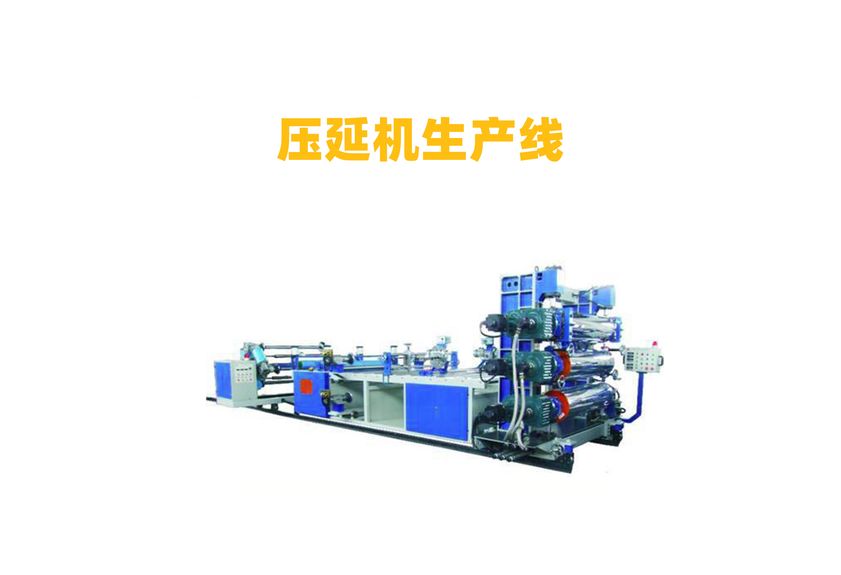

The pressing machine used to produce these graphene-based thermal conductive pads plays a crucial role in ensuring consistent quality and uniformity in the final product. The machine employs advanced technology to precisely control the placement and alignment of the graphene layers, resulting in a seamless integration with the substrate. This precision ensures that each pad meets the required thermal performance standards, providing consistent results across different applications.

One of the key advantages of using graphene-based thermal conductive pads is their ability to reduce power consumption in electronic devices. By efficiently dissipating heat generated by the device, these pads can help extend the lifespan of the device and improve overall performance. Additionally, they can help reduce the risk of overheating, which can lead to device failure or damage.

Another significant benefit of graphene-based thermal conductive pads is their compatibility with various materials. These pads can be integrated into a wide range of substrates, including metal, plastic, and glass, without any issues. This flexibility makes them ideal for use in a variety of applications, from electronics to automotive components.

In conclusion, the graphene-based thermal conductive pad presses offer a powerful solution for improving thermal management in electronic devices and other applications. With their exceptional thermal conductivity properties and ease of integration, these pads are set to become a staple in the industry for years to come. As technology continues to advance, we can expect to see even more innovative solutions that leverage the power of graphene-based thermal conductive pads to enhance performance and reliability in a wide range of applications.